Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Open access

- Published: 18 March 2022

Large-scale synthesis of graphene and other 2D materials towards industrialization

- Soo Ho Choi ORCID: orcid.org/0000-0002-9927-0101 1 , 2 na1 ,

- Seok Joon Yun 1 , 2 na1 ,

- Yo Seob Won 2 ,

- Chang Seok Oh 2 ,

- Soo Min Kim 3 ,

- Ki Kang Kim ORCID: orcid.org/0000-0003-1008-6744 1 , 2 &

- Young Hee Lee ORCID: orcid.org/0000-0001-7403-8157 1 , 2

Nature Communications volume 13 , Article number: 1484 ( 2022 ) Cite this article

26k Accesses

173 Citations

7 Altmetric

Metrics details

- Electronic devices

- Synthesis and processing

- Synthesis of graphene

- Two-dimensional materials

The effective application of graphene and other 2D materials is strongly dependent on the industrial-scale manufacturing of films and powders of appropriate morphology and quality. Here, we discuss three state-of-the-art mass production techniques, their limitations, and opportunities for future improvement.

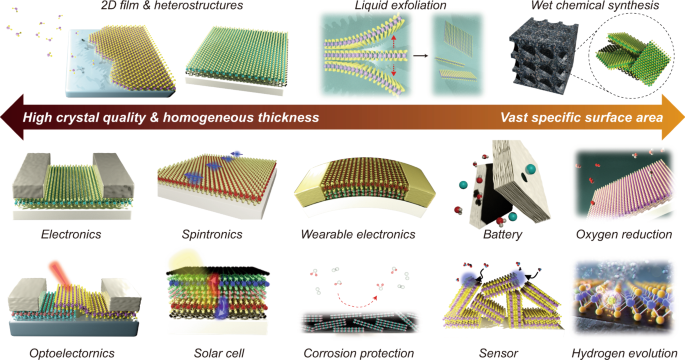

Two-dimensional (2D) van der Waals (vdW) layered materials including graphene, transition metal dichalcogenides (TMDs), hexagonal boron nitride (hBN), and MXenes have attracted much attention in recent years. This is due to their distinctive physical and chemical properties, such as their quantum Hall effects and quantum valley Hall effects, indirect-to-direct bandgap transition, and strong spin-orbit coupling 1 , which have not been accessible with conventional 3D bulk materials. In addition, vertical vdW heterostructures constructed by layer-by-layer stacking enable interesting applications for atomically thin quantum wells, p-n junctions, Coulomb drag transistors, and twistronic devices 1 , 2 , 3 . However, applications based on such structures are limited by the fact that most vdW materials are currently only available with a lateral size of up to a few tens of micrometers. Techniques for the large-scale synthesis of 2D materials will therefore be required for industrialization. Moreover, since specific applications of these materials are strongly dependent on characteristics such as their morphology and quality, mass production techniques should also be developed that can accommodate such requirements (Fig. 1 ). In general, most applications rely on either films or powders of vdW materials. Films require high crystal quality, and can be used in the context of electronics, spintronics, optoelectronics, twistronics, or solar cells, whereas powders exhibit large surface areas and are employed in the construction of batteries, sensors, and catalysts. At present, only large-area graphene films and graphite oxide powders are currently available in the commercial market 4 . In this Comment, we briefly examine research trends in synthesis techniques and their associated challenges for the industrialization of 2D layered materials.

2D films and heterostructures require high crystal quality and homogeneous thickness for applications such as electronics and spintronics, whereas high-porosity powders with vast specific surface area can be used in contexts such as catalysts and energy storage.

Three representative synthesis techniques

There are currently three representative synthesis techniques available for the large-scale synthesis of 2D materials. The first is chemical vapor deposition (CVD); although a variety of thin-film deposition techniques have been investigated for growing large-area 2D films, including pulsed laser deposition (PLD) 5 , atomic layer deposition (ALD) 6 , and molecular beam epitaxy (MBE) 7 , CVD is most feasible for industrialization when one takes into account the uniformity and crystallinity of 2D films as well as requirements of high throughput, cost effectiveness, and scalability. The other two techniques being investigated for mass production are top-down liquid exfoliation of 2D materials and bottom-up wet chemical synthesis.

CVD for growing large-scale 2D thin films

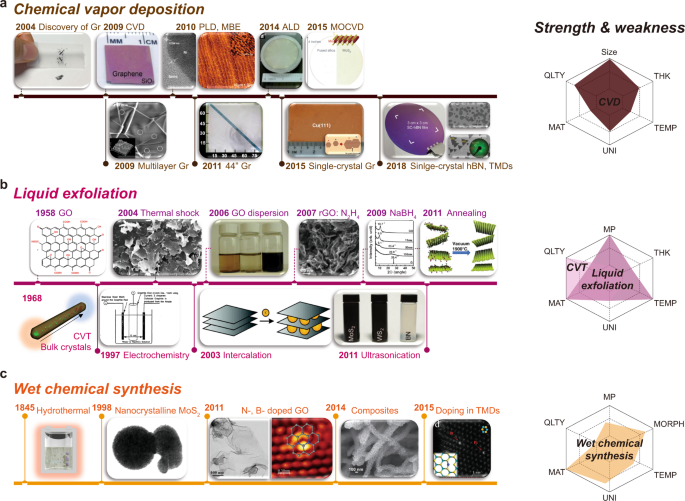

There are multiple examples of CVD synthesis of thin films at wafer scale (Fig. 2a ). For example, wafer-scale polycrystalline monolayer and multilayer graphene films have been successfully synthesized by CVD on polycrystalline Cu and Ni foils since 2009 8 , 9 , 10 , 11 , and wafer-scale single-crystal monolayer graphene has been synthesized by using single-crystal substrates such as H–Ge (110) and Cu (111) 12 , 13 . Single-crystal multilayer graphene films have been also grown on Si–Cu alloys at wafer scale 14 . In 2012, centimeter-scale polycrystalline monolayers of hBN and TMDs were grown on polycrystalline Cu foils and SiO 2 /Si substrates, respectively 15 , 16 . And more recently, single-crystal hBN and TMD films were successfully synthesized on liquid Au, high-index single-crystal Cu surfaces, and atomic sawtooth Au surfaces 17 , 18 .

Lefthand panels show timelines of milestones for a chemical vapor deposition (CVD), b liquid exfoliation, and c wet chemical synthesis methods. The abbreviations correspond to: metal-organic CVD (MOCVD), graphene (Gr), graphite oxide (GO), reduced GO (rGO), and molybdenum disulfide (MoS 2 ). Righthand panels show the corresponding strengths and weaknesses of these methods in terms of mass production (MP), thickness controllability (THK), temperature variation (TEMP), uniformity (UNI), material diversity (MAT), crystal quality (QLTY), morphology (MORPH). Panel a reprinted from refs. 9 , 17 , American Association for the Advancement of Science, ref. 15 , Nature, refs. 7 , 10 , 12 , Wiley, ref. 5 , American Institute of Physics, ref. 6 , Royal Society of Chemistry, and ref. 11 , World Scientific. Panel b reprinted from refs. 26 , 27 , American Association for the Advancement of Science, refs. 22 , 23 , Wiley, refs. 19 , 20 , 21 , Elsevier, and ref. 24 , Institute of Electrical and Electronic Engineers. Panel c reprinted from ref. 28 , Elsevier, ref. 30 , American Chemical Society, ref. 31 , Elsevier, and ref. 32 , Royal Society of Chemistry.

CVD produces relatively high-quality 2D films under atmospheric or low pressure, and the size of the film can easily be scaled up by increasing the chamber size. However, high temperature reactions (above 500 °C) are required, which could be a drawback for industrialization. The growth of a vast range of 2D materials, including graphene, hBN, and TMDs, is still limited by the absence of appropriate precursors. Perhaps the most important technical challenge presented by this method is the poor control over the number of synthesized layers, because the absence of dangling bonds on the surface of 2D vdW materials makes epitaxial growth difficult.

Liquid exfoliation

Liquid exfoliation is a powerful process for the mass production of pristine 2D bulk materials by dispersing them into individual sheets. Bulk materials have been synthesized by chemical vapor transport (CVT) (Fig. 2b ) since the late 1960s, but most 2D bulk materials are currently only available in small quantities. Nanodispersion into monolayers is often required to manifest the unique 2D nature, but the strong vdW energy of micron-scale materials hinders facile exfoliation. Thus, two additional steps should be considered for liquid exfoliation processes: (i) weakening the layer-layer interaction by expanding the interlayer distance, and (ii) physical agitation for dispersion 19 , 20 . In 1958, it was demonstrated that the interlayer distance can be increased from 3.4 to 7.0 Å by the oxidation of graphite, known as “graphite oxide”, and such an expansion of the interlayer distance made it possible to disperse the individual graphite oxide layers by sonication. Graphite oxide layers can subsequently be reduced to graphene nanosheets through chemical treatment with reducing agents and thermal annealing treatment 21 , 22 , 23 .

The lattice of graphene nanosheets is often severely damaged during oxidation and reduction processes. To prevent this, the interlayer distance can be increased by intercalating ions and molecules between layers. Electrochemistry enables effective intercalation of both cations and anions in an electrolyte solution by applying negative and positive bias, respectively 24 . Alkali metals, organic solvents, and surfactants with similar surface energies to those of the 2D materials can also be directly intercalated in liquid or vapor phase 25 , 26 . After intercalation, agitation methods such as sonication, homogenization, and microwave treatment can be employed to exfoliate materials into individual 2D layers 27 . Liquid exfoliation enables mass production of 2D nanosheets under atmospheric pressure at room temperature. However, this approach also leads to presumably unavoidable damage and non-uniform nanosheet thickness.

Wet chemical synthesis

Hydrothermal and solvothermal syntheses are representative wet chemical synthesis methods, in which materials are respectively solubilized in aqueous solution and organic solvent under high vapor pressure at elevated temperatures (~300 °C). A variety of nanomaterials have been synthesized in this fashion since the first report of hydrothermal synthesis of microscopic quartz crystals in 1845 (Fig. 2c ). The wet chemical synthesis of pure 2D materials such as graphene and MoS 2 surged in the early 21st century 28 , 29 , and more recently, doped 2D materials, nanocomposites, and their heterostructures have been synthesized in this fashion by adding various precursors and dopants in solvent to enhance the material properties for specific applications 30 , 31 , 32 , 33 . For example, the hydrogen evolution reaction in graphene oxide was dramatically enhanced by introducing boron dopants 33 .

The strengths of wet chemical synthesis include the controllability of surface morphology, crystallite size, and dopants in 2D materials for catalyst, energy storage, and chemical/biological sensor applications. Reaction temperatures, precursors, and additives have been optimized for various types of 2D materials and their composites, enabling essentially unlimited mass production. The direct synthesis of 2D materials on a desired substrate is also possible, although such synthesis takes a relatively longer time—up to a few days. Growth temperature is often limited to below 300 °C due to the limited durability of equipment under harsh conditions including high pressure and exposure to corrosive chemicals. It is worth noting that bottom-up synthesis tends to yield low-quality 2D materials with defects, but it is still possible to employ these for catalytic applications.

Perspectives and challenges toward industrialization

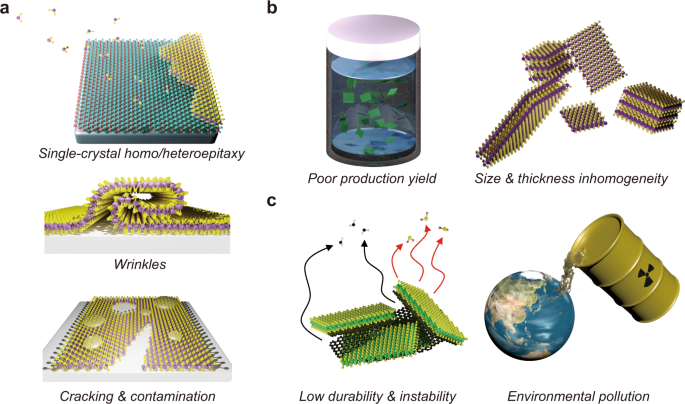

The abovementioned techniques enable mass production of 2D materials, but considerable further advances will be required for some specific applications. Single-crystal graphene films have been successfully synthesized at wafer scale with layer control, but the synthesis of other 2D materials such as hBN and TMDs are limited exclusively to single-crystal monolayer films. Thickness control of such materials is essential for tunneling barrier and high-performance electronics. The combination of tunable bandgap semiconductors, metals, and insulators in 2D systems can generate versatile heterostructures with remarkable physical properties. Several planar and vertical heterostructures have been generated to date, but these remain limited to micron scale 34 , 35 . More generally, the growth of various heterostructures at wafer scale is still challenging (Fig. 3a ). Atomic sawtooth surfaces could be ideal as a growth platform for single-crystal 2D materials including graphene, hBN, TMDs, and their heterostructures, but surface facet control remains elusive. The formation of wrinkles in 2D films after high temperature growth is another important issue, originating from the thermal expansion coefficient mismatch between 2D materials and growth substrate. Recently, the growth of fold-free single-crystal graphene films at 750 °C has been reported 36 , but further investigation will be required to see if this method is applicable for other 2D materials, and lower-temperature growth methods should be established.

a Single-crystal homo/heteroepitaxial growth, wrinkle formation by thermal expansion coefficient mismatch between 2D materials and growth substrates, and cracking/contamination during the transfer process are all issues presented by the CVD technique. b Inhomogeneous size and thickness of 2D nanosheets and poor production yield are problems associated with liquid exfoliation. c Low durability and instability of 2D materials by defects and environmental pollution remain challenges for wet chemical synthesis.

High temperature processes (above 400 °C) are not compatible with current Si technology, and 2D thin films grown by CVD at high temperature must therefore be transferred onto a target substrate. A conventional transfer process can give rise to serious problems such as folding and cracking of 2D films, ultimately degrading film homogeneity and device performance. Furthermore, the polymer contaminants that are commonly introduced as a supporting layer for the transfer process can give rise to unintentional doping and high contact resistance in heterostructure interfaces and devices. Therefore, methods for the direct growth of large-area 2D films by CVD or advanced roll-to-roll transfer technique would be highly desirable. For industrialization, the manufacturing process including scalable techniques (roll-to-roll, batch-to-batch, etc.), production capacity/cost, reproducibility, and large-area uniformity are further considered 37 .

Wet chemical processes including liquid exfoliation and wet chemical synthesis also face several challenges for the mass production of 2D materials. Liquid exfoliation employs pristine 2D bulk materials synthesized by CVT or flux methods for the mass production of 2D nanosheets. Those synthetic methods typically take at least one week, lowering the throughput of production, and companies need the capacity to provide these bulk materials at a larger scale. Additionally, the production yield of liquid exfoliation generally remains poor, and although some materials show relatively high yield, most 2D materials like hBN and telluride are not effectively exfoliated with current techniques. In addition, it is difficult to obtain 2D nanosheets of uniform size and thickness with this method (Fig. 3b ). In order to remedy this, improved techniques for sorting the synthesized nanosheets in terms of size and thickness (e.g., density gradient ultracentrifugation) are needed.

Bottom-up chemical synthesis typically produces 2D materials with low crystal quality. The defect sites (i.e., edges) often serve as active sites for 2D catalyst, but also give rise to low durability and instability issues. Moreover, 2D materials generated by chemical synthesis are not uniformly distributed in terms of size and thickness, requiring special care during synthesis. In addition, the byproducts frequently generated during chemical synthesis can inhibit catalytic activity. To resolve these material quality and byproduct issues, post-treatments such as thermal annealing and purification have been suggested, but a simple process without post-treatment would greatly improve productivity. Another important issue is the environmental pollution caused by the large amount of hazardous chemical wastes used in synthesis (Fig. 3c ), and the use of supercritical fluid regions could be considered as a shortcut to minimize chemical use 38 .

In addition, rapid and reliable non-destructive characterization tools are highly required to evaluate the wafer-scale 2D materials in terms of sample quality and uniformity. The current state-of-the-art terahertz image, phase-shift interferometry, and wide-field Raman imaging could be adopted to analyze the electrical and optical properties of 2D films with short acquisition time of a few seconds per mm 2 and high spatial resolution of an order of micrometers 39 , 40 , 41 . It still requires a prolonged period to thoroughly inspect 12-inch wafer-scale sample, and therefore, the development of advanced characterization tools is further desired.

From a materials point of view, there is plenty of room for unexplored novel 2D materials and their vdW heterostructures. Since it is almost impossible to explore all such materials experimentally, artificial intelligence-based material design could prove useful for the industrialization and large-scale manufacture of such newly-developed 2D materials 42 .

Novoselov, K. S., Mishchenko, A., Carvalho, A. & Neto, A. H. C. 2D materials and van der Waals heterostructures. Science 353 , aac9439 (2016).

Article CAS PubMed Google Scholar

Jin, Y. et al. Coulomb drag transistor using a graphene and MoS 2 heterostructure. Commun. Phys. 3 , 189 (2020).

Article CAS Google Scholar

Cao, Y. et al. Unconventional superconductivity in magic-angle graphene superlattices. Nature 556 , 43–50 (2018).

Article ADS CAS PubMed Google Scholar

Lin, L., Peng, H. L. & Liu, Z. F. Synthesis challenges for graphene industry. Nat. Mater. 18 , 520–524 (2019).

Koh, A. T. T., Foong, Y. M. & Chua, D. H. C. Cooling rate and energy dependence of pulsed laser fabricated graphene on nickel at reduced temperature. Appl. Phys. Lett. 97 , 114102 (2010).

Article ADS Google Scholar

Tan, L. K. et al. Atomic layer deposition of a MoS 2 film. Nanoscale 6 , 10584–10588 (2014).

Park, J. et al. Epitaxial graphene growth by carbon molecular beam epitaxy (CMBE). Adv. Mater. 22 , 4140–4145 (2010).

Zhang, Y., Zhang, L. Y. & Zhou, C. W. Review of chemical vapor deposition of graphene and related applications. Acc. Chem. Res. 46 , 2329–2339 (2013).

Li, X. S. et al. Large-area synthesis of high-quality and uniform graphene films on copper foils. Science 324 , 1312–1314 (2009).

Chae, S. J. et al. Synthesis of large-area graphene layers on poly-nickel substrate by chemical vapor deposition: Wrinkle formation. Adv. Mater. 21 , 2328–2333 (2009).

Han, G. H. et al. Poly(ethylene co-vinyl acetate)-assisted one-step transfer of ultra-large graphene. Nano 6 , 59–65 (2011).

Nguyen, V. L. et al. Seamless stitching of graphene domains on polished copper (111) foil. Adv. Mater. 27 , 1376–1382 (2015).

Nguyen, V. L. & Lee, Y. H. Towards wafer-scale monocrystalline graphene growth and characterization. Small 11 , 3512–3528 (2015).

Nguyen, V. L. et al. Layer-controlled single-crystalline graphene film with stacking order via Cu–Si alloy formation. Nat. Nanotechnol. 15 , 861–867 (2020).

Kang, K. et al. High-mobility three-atom-thick semiconducting films with wafer-scale homogeneity. Nature 520 , 656–660 (2015).

Cai, Z. Y., Liu, B. L., Zou, X. L. & Cheng, H. M. Chemical vapor deposition growth and applications of two-dimensional materials and their heterostructures. Chem. Rev. 118 , 6091–6133 (2018).

Lee, J. S. et al. Wafer-scale single-crystal hexagonal boron nitride film via self-collimated grain formation. Science 362 , 817–821 (2018).

Choi, S. H. et al. Epitaxial single-crystal growth of transition metal dichalcogenide monolayers via the atomic sawtooth Au surface. Adv. Mater. 33 , 2006601 (2021).

Chen, G. H. et al. Preparation and characterization of graphite nanosheets from ultrasonic powdering technique. Carbon 42 , 753–759 (2004).

Stankovich, S., Piner, R. D., Nguyen, S. T. & Ruoff, R. S. Synthesis and exfoliation of isocyanate-treated graphene oxide nanoplatelets. Carbon 44 , 3342–3347 (2006).

Stankovich, S. et al. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 45 , 1558–1565 (2007).

Shin, H. J. et al. Efficient reduction of graphite oxide by sodium borohydride and its effect on electrical conductance. Adv. Funct. Mater. 19 , 1987–1992 (2009).

Jin, M. H. et al. Facile physical route to highly crystalline graphene. Adv. Funct. Mater. 21 , 3496–3501 (2011).

Kozawa, A., Fujita, K., Sato, A. & Brodd, D. Recent new additives for electric vehicle lead-acid batteries for extending the cycle life and capacity. In Twelfth Annual Battery Conference on Applications and Advances . 277–282 (IEEE, 1997).

Wan, J. Y. et al. Tuning two-dimensional nanomaterials by intercalation: Materials, properties, and applications. Chem. Soc. Rev. 45 , 6742–6765 (2016).

Viculis, L. M., Mack, J. J. & Kaner, R. B. A chemical route to carbon nanoscrolls. Science 299 , 1361–1361 (2003).

Coleman, J. N. et al. Two-dimensional nanosheets produced by liquid exfoliation of layered materials. Science 331 , 568–571 (2011).

Zhan, J. H. et al. Solvothermal synthesis of nanocrystalline MoS 2 from MoO 3 and elemental sulfur. J. Solid State Chem. 141 , 270–273 (1998).

Article ADS CAS Google Scholar

Yang, L. S., Chen, W. J., Yu, Q. M. & Liu, B. L. Mass production of two-dimensional materials beyond graphene and their applications. Nano Res 14 , 1583–1597 (2021).

Deng, D. H. et al. Toward N-doped graphene via solvothermal synthesis. Chem. Mater. 23 , 1188–1193 (2011).

Wang, J. et al. Ni 3 S 2 @MoS 2 core/shell nanorod arrays on Ni foam for high-performance electrochemical energy storage. Nano Energy 7 , 151–160 (2014).

Deng, J. et al. Triggering the electrocatalytic hydrogen evolution activity of the inert two-dimensional MoS 2 surface via single-atom metal doping. Energy Environ. Sci. 8 , 1594–1601 (2015).

Sathe, B. R., Zou, X. X. & Asefa, T. Metal-free B-doped graphene with efficient electrocatalytic activity for hydrogen evolution reaction. Catal. Sci. Technol. 4 , 2023–2030 (2014).

Article Google Scholar

Duong, D. L., Yun, S. J. & Lee, Y. H. van der Waals layered materials: Opportunities and challenges. ACS Nano 11 , 11803–11830 (2017).

Li, M. Y., Chen, C. H., Shi, Y. M. & Li, L. J. Heterostructures based on two-dimensional layered materials and their potential applications. Mater. Today 19 , 322–335 (2016).

Wang, M. et al. Single-crystal, large-area, fold-free monolayer graphene. Nature 596 , 519–524 (2021).

Lin, L. & Liu, Z. Synthesis challenges for graphene industry. Nat. Mater. 18 , 520–524 (2019).

Takahashi, Y., Nakauasu, Y., Iwase, K., Kobayashi, H. & Honma, I. Supercritical hydrothermal synthesis of MoS 2 nanosheets with controllable layer number and phase structure. Dalton Trans. 49 , 9377–9384 (2020).

Lee, U. et al. Facile morphological qualification of transferred graphene by phase-shifting interferometry. Adv. Mater. 32 , 2002854 (2020).

Havener, R. W. et al. High-throughput graphene imaging on arbitrary substrates with widefield Raman spectroscopy. ACS Nano 6 , 373–380 (2012).

Scarfe, S., Cui, W., Luican-Mayer, A. & Ménard, J.-M. Systematic THz study of the substrate effect in limiting the mobility of graphene. Sci. Rep. 11 , 8729 (2021).

Article ADS CAS PubMed PubMed Central Google Scholar

Cai, J. Z., Chu, X., Xu, K., Li, H. B. & Wei, J. Machine learning-driven new material discovery. Nanoscale Adv. 2 , 3115–3130 (2020).

Download references

Acknowledgements

K.K.K. acknowledges support by Samsung Research Funding & Incubation Center of Samsung Electronics under Project Number SRFC-MA1901-04, the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT & Future Planning (2018R1A2B2002302 and 2020R1A4A3079710). K.S.M. acknowledges support by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT & Future Planning (2022R1A2C2009292). Y.S.J., C.S.H., K.K.K., and L.Y.H. acknowledge support by the Institute for Basic Science (IBS-R011-D1).

Author information

These authors contributed equally: Soo Ho Choi, Seok Joon Yun.

Authors and Affiliations

Center for Integrated Nanostructure Physics, Institute for Basic Science (IBS), Suwon, 16419, Republic of Korea

Soo Ho Choi, Seok Joon Yun, Ki Kang Kim & Young Hee Lee

Department of Energy Science, Sungkyunkwan University, Suwon, 16419, Republic of Korea

Soo Ho Choi, Seok Joon Yun, Yo Seob Won, Chang Seok Oh, Ki Kang Kim & Young Hee Lee

Department of Chemistry, Sookmyung Women’s University, Seoul, 14072, Republic of Korea

Soo Min Kim

You can also search for this author in PubMed Google Scholar

Contributions

C.S.H., Y.S.J., K.S.M., K.K.K., and L.Y.H. designed and developed this work. W.Y.S., O.C.S., Y.S.J., and C.S.H. investigated the history and technical issues of the various production methods. All authors participated in the writing manuscript.

Corresponding authors

Correspondence to Soo Min Kim , Ki Kang Kim or Young Hee Lee .

Ethics declarations

Competing interests.

The authors declare no competing interests.

Peer review

Peer review information.

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Cite this article.

Choi, S.H., Yun, S.J., Won, Y.S. et al. Large-scale synthesis of graphene and other 2D materials towards industrialization. Nat Commun 13 , 1484 (2022). https://doi.org/10.1038/s41467-022-29182-y

Download citation

Received : 03 November 2021

Accepted : 24 February 2022

Published : 18 March 2022

DOI : https://doi.org/10.1038/s41467-022-29182-y

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

This article is cited by

A clean transfer approach to prepare centimetre-scale black phosphorus crystalline multilayers on silicon substrates for field-effect transistors.

- Yuqian Zhao

- Jianfeng Mao

- Jianhua Hao

Nature Communications (2024)

Functional nanoporous graphene superlattice

- Hualiang Lv

- Xiaoguang Wang

Selenium-alloyed tellurium oxide for amorphous p-channel transistors

- Yong-Sung Kim

- Yong-Young Noh

Nature (2024)

Solid-state surfactant templating for controlled synthesis of amorphous 2D oxide/oxyhydroxide nanosheets

- Eisuke Yamamoto

- Daiki Kurimoto

- Minoru Osada

Metal telluride nanosheets by scalable solid lithiation and exfoliation

- Liangzhu Zhang

- Zixuan Yang

- Hui-Ming Cheng

Quick links

- Explore articles by subject

- Guide to authors

- Editorial policies

Sign up for the Nature Briefing newsletter — what matters in science, free to your inbox daily.

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Animals (Basel)

Mass Production of the Black Soldier Fly, Hermetia illucens (L.), (Diptera: Stratiomyidae) Reared on Three Manure Types

Chelsea d. miranda.

1 EVO Conversion Systems, LLC, College Station, TX 77845, USA; moc.sysnocove@kcammacaj

Jonathan A. Cammack

Jeffery k. tomberlin.

2 Department of Entomology, Texas A&M University, College Station, TX 77843, USA; ude.umat@nilrebmotkj

Simple Summary

The black soldier fly (BSF) has gained a considerable amount of attention globally for its ability to convert organic material into valuable biomass for waste management and food and feed purposes. As the industry of producing BSF expands, connecting research and application is necessary to optimize mass-production facilities. Historically, research on the BSF has been conducted at a benchtop scale. Expanding these results to industrial practices is challenging, as results typically are not scalable. This study investigates the production of BSF fed animal manure (swine, dairy, and poultry) at a larger scale (thousands of larvae fed kg of diet) than what has been previously published (small-scale studies with hundreds of larvae fed g of diet).

Recent interest in the mass production of black soldier fly (BSF) larvae has resulted in many studies being generated. However, a majority of the studies are benchtop, or small-scale, experiments. Results generated from such studies may not translate to large-scale/industrial production. The current study was conducted at a conventional large-scale (10,000 larvae/treatment fed seven kg) to determine the impact on selected life-history traits when BSF were fed seven kg of manure (swine, dairy, or poultry) or a control diet (Gainesville diet: 50% wheat bran, 30% alfalfa meal, and 20% corn). Results showed larvae fed dairy manure took one to two days longer to develop to prepupation, with lower survivorship (45%) compared to those fed poultry or swine manure (>70%). Furthermore, the maximum larval weight was reached on day six for those fed swine manure, while other treatments achieved the maximum weight on day seven. However, larvae fed swine manure averaged 150 mg, while those fed the other diets ranged between 175 and 200 mg. Data from this study may be valuable for the industrialization of BSF. Companies using a scale varying from previously published work, including this study, should conduct pilot studies to optimize their system prior to implementation.

1. Introduction

Insects provide a variety of goods and services for human exploitation [ 1 ]. They may be reared for medicinal purposes, such as wound therapy [ 2 ], or to engineer antibodies [ 3 ] and vaccines [ 4 ]. They may be cultivated for other well-known purposes, such as honey [ 5 ], silk [ 6 ], and dye production [ 7 ], or can be used to control insect pest populations [ 8 ]. Insects may also be used for food and feed purposes [ 9 ]; however, this industry is still in its infancy in terms of operating on an industrial scale. Recent interest in exploiting insects in this manner has prompted numerous studies [ 10 , 11 , 12 , 13 , 14 ], which helps progress the idea and refine the industry; however, a majority of the published studies are based on small-scale (benchtop) experiments, which may not truly represent what occurs on a larger industrial scale.

The black soldier fly (BSF), Hermetia illucens (L.), (Diptera: Stratiomyidae) has gained a considerable amount of attention. As discussed in previous publications, this species is distributed globally throughout temperate and tropical regions and is an ideal candidate for industrialization purposes, because it offers a means to manage a variety of wastes [ 15 , 16 , 17 ] and provides multiple revenue streams, such as the production of animal feed [ 9 ], biofuel [ 18 , 19 ], and fertilizer [ 20 ]. In systems using manure as a resource, the BSF reduces dry matter [ 21 ], pathogens [ 22 , 23 ], and odors [ 24 ]. However, most previously published work on BSF was performed on a small scale (e.g., several hundred larvae per replicate), which may not translate to an industrial scale.

Methods used in small-scale studies are typically different than those employed by mass-production facilities (larval numbers in the thousands and fed kilograms of substrate rather than hundreds of larvae consuming grams over time). Both factors are known to impact development. For example, Banks et al. [ 25 ] showed that bulk feeding increased the development time and larval weight across three densities (1, 10, and 100 larvae) compared to those fed incrementally. Similarly, Barragán-Fonseca et al. [ 26 ] found that, with small-scale densities (50, 100, 200, or 400 larvae), an increased larval density lead to greater delays in development (up to 45 days) on low-nutrient diets but not on high-nutrient diets. Variations in the development time, larval and adult weights, and survivorship have also been reported across different larval densities (500–2000 larvae) of BSF fed the same diet [ 27 ]. Even the authors of the study being presented here have conducted such studies [ 28 , 29 ]. However, all of these studies are considered small-scale when compared to practices in the industry, and it is not known if similar results would occur on a larger scale.

Larval BSF density can hinder or, in some instances, enhance their performance. Bryant and Sokal [ 30 ] showed that low densities (80 eggs/18,000 mg of diet) and high densities (640 eggs/18,000 mg of diet) of house flies, Musca domestica L., (Diptera: Muscidae) faced different consequences during development. Low densities may result in poor conditioning of the diet (via metabolites produced by larvae), which impacts yeast growth and, ultimately, the availability of food [ 30 ]. However, an increased larval density may intensify the effects of competition, leading to reduced survivorship [ 30 , 31 ]. Larvae feed in aggregates generate heat [ 32 ], which, in turn, impacts BSF development and survivorship. Black soldier fly larvae reared at 30 °C developed the fastest (13 d), had the shortest prepupal development (8–10 d), and had the highest larval survivorship (90%) compared to those reared on temperatures that ranged from 10–42 °C [ 33 ]. Additionally, it is possible that higher densities produced more oral secretions (gut microbiota) that aided in the cooperative digestion of a resource [ 34 ]. As such, the larval density is a major factor that influences BSF performance.

The purpose of this study was to evaluate selected life-history traits of BSF fed swine, dairy, or poultry manure by using methods based on industrial standards [ 35 ]. Most of the data available on this species originates from small-scale studies, which may not translate to a larger production scale, as previously discussed. Results from this study may be valuable by providing a basis to compare findings from previous small-scale studies, as well as a paradigm to help optimize the mass-rearing conditions of BSF fed manure.

2.1. Acquisition of BSF

Methods for this study were based on those conducted by Miranda et al. [ 29 ]. Black soldier flies were obtained from a colony that is maintained at the F.L.I.E.S. (Forensic Laboratory for Investigative Entomological Sciences) Facility at Texas A&M University in College Station, TX, USA. The colony originated from a colony maintained in Tifton, GA, USA and was maintained following modified methods proposed by Sheppard et al. [ 36 ].

2.2. Acquisition of Manure

Manure less than 12-h-old was used in this study. Swine manure was collected from a farm in Anderson, TX, USA, dairy manure was collected from a commercial dairy located in Stephenville, TX, USA, and poultry manure was collected from layer hens housed at the Poultry Science Research, Teaching and Extension Center at Texas A&M University, College Station, TX, USA. Manure was placed into 18.9 L buckets, covered with lids (Home Depot ® , Leaktite™, Leominster, MA, USA), and transported to the F.L.I.E.S. Facility, where it was homogenized by hand-mixing for 5 min, transferred to 3.7 L Ziploc ® Freezer bags (S.C. Johnson & Son, Inc., Racine, WI, USA), and stored at −20°C until used. Before initiation of the experiment, the manure was allowed to thaw at room temperature for 24 h. Moisture contents of manure were measured gravimetrically with three 10 g samples following the methods described by Franson [ 37 ]. Initial moisture content for swine, dairy, and poultry manure were 72%, 83%, and 77%, respectively.

2.3. Experiment Design

Black soldier fly adults were maintained at the F.L.I.E.S. (Forensic Laboratory for Investigative Entomological Sciences) Facility in a 260 × 116 × 129 cm wooden cage lined with a fiberglass window screen (18 × 16 mesh size) in a greenhouse (25 °C, >50% relative humidity (RH)). To collect eggs, a 5.7 L Sterilite ® container (Sterilite ® , Townsend, MA, USA) was filled with 500 g Gainesville diet (50% wheat bran, 30% alfalfa meal, and 20% corn meal) [ 38 ] saturated with RO (reverse osmosis) water (70%). Corrugated cardboard was cut into 5.0 × 2.0 × 0.5 cm pieces with five taped together to form a bundle, which was placed on the lid of the container described above. The lid of the container had a 15 × 7 cm hole cut in the center of the lid and was covered with wire mesh. The container remained in the wooden cage for 8 h, after which the cardboard was removed from the cage and placed in a 0.9 L Ball ® mason jar (Ball Corporation, Broomfield, CO, USA) covered with a paper towel, which was secured with the metal ring of the mason jar lid. The jar with the cardboard containing the eggs was stored in a Rheem Environmental Chamber (Asheville, NC, USA; 29 °C, 60% RH, and 16L:8D (light:dark)) until larvae were enclosed. Ten replicates of 100 newly-hatched larvae were hand counted and then weighed on an OHaus ® Adventure ™ Pro AV64 balance (OHaus ® Corporation, Pine Brook, NJ, USA) to get the average weight of an individual larvae, which was then used to weigh approximately 10,000 larvae per replicate. Larvae were placed in 0.5 L deli food storage containers (Amazon.com Inc., Seattle, WA, USA) without a lid and were fed 150 g of Gainesville diet (70% moisture) for four days to decrease larval mortality prior to use in the experiment.

Treatments consisted of 10,000 4-d-old larvae fed 7 kg of swine, dairy, or poultry manure. Larvae in control groups were fed 7 kg of Gainesville diet (70% moisture). Larval diets were placed in the center of a 30 L Sterilite ® ClearView Latch ™ storage container, with 700 g of dry Gainesville diet [ 38 ] placed around the perimeter of the wet diet to serve as a pupation substrate and to prevent developing larvae from escaping. Larvae were weighed prior to placement on the manure or Gainesville diets to determine that their weights were not significantly different. The deli containers with developing larvae were poured on top of the diets, and the containers (with the larvae and diets) were placed inside the environmental chamber (via complete randomized block design) described above. Three replicates of each treatment and control were used, and two trials were conducted.

Larvae were allowed to feed on the manure or Gainesville diets for two days prior to measuring the daily larval weight, as they were too small to find without significantly disturbing the media. The daily larval weight was measured by attempting to select 10 of the largest larvae for nine days, and a different set of larvae was selected each day. The development time to first prepupation was recorded upon observation of the first prepupa within a given container. On the day the first prepupa was observed, larvae were sifted from the media, and survivorship was calculated by dividing the total weight of all living larvae from each replicate by the average final larval weight. After the total larval weight was recorded, larvae were placed in 30 L Sterilite ® containers with 1 kg of dry Gainesville diet. The prepupal weight was measured by selecting 10 of the largest prepupae from each replicate when 40% reached the prepupal stage. All weights were measured using the balance described above.

2.4. Statistical Analyses

Larval weight, development time from placement on the manure to prepupation, percent prepupation (survivorship), and prepupal weight were analyzed across treatments and trials. An ANOVA was performed for each parameter listed. Statistics were performed using JMP ® PRO 14 (SAS Institute Inc., Cary, NC, USA). Normality was checked using a Shapiro-Wilk test, and equality of variance was checked using a Bartlett’s test. Tukey’s HSD (honest significant difference) was used for mean separation ( p ≤ 0.05).

3.1. Larval Weight

Larval weight did not differ significantly across larval diets (F 3,142 = 1.9318; p = 0.1263). A significant trial effect was found (F 1,142 = 163.6540; p < 0.0001), but no significant treatment by trial interaction was found (F 27,142 = 0.7314; p = 0.8178). In general, individuals in trial two weighed 22% more than those in trial one. Larvae reared on swine manure reached a maximum weight on day six, while those fed the other diets did so on day seven. Furthermore, the maximum weight of larvae fed swine manure (150 mg) was less than those fed the other diets (175 to 200 mg) ( Figure 1 ).

Mean larval weight (mg) ± SEM ( 1 n = 6) of black soldier flies fed 7 kg of swine, dairy, or poultry manure or the Gainesville control diet [ 38 ] at 29 °C, 60% relative humidity (RH), and 16L:8D. 1 n = number of replicates per treatment.

3.2. Development Time to First Prepupation

Development time to first prepupation differed significantly (F 3,16 = 16.9048; p < 0.001) across the larval diets. No trial effect (F 1,16 = 0.1429; p = 0.7104) or treatment by trial interaction (F 3,16 = 0.5238; p = 0.6721) was found. The shortest development time was found for those fed the Gainesville diet (13 d). In regard to those fed manure, the shortest development time was found for those fed poultry (14 d) and swine manures (15 d), whereas those fed dairy manure took an additional day (16 d) to reach prepupation ( Figure 2 ).

Development time (d) to first prepupation (mean ± SE, 1 n = 6) of black soldier fly larvae fed 7 kg of swine, dairy, or poultry manure or the Gainesville control diet [ 38 ] at 29 °C, 60% RH, and 16L:8D. Different letters (A–C) indicate significant differences between treatments (α = 0.05) and ANOVA, followed by Tukey’s HSD. 1 n = number of replicates per treatment.

3.3. Percent Prepupation

Survivorship to prepupation was significantly different (F 3,16 = 22.2899; p < 0.0001) across the larval diets. No trial effect (F 1,16 = 0.6001; p = 0.4498) or treatment by trial interaction (F 3,16 = 1.2535; p = 0.3235) was found. The highest percent prepupation across all diets was found for those fed the Gainesville diet (88%). Survivorship to prepupation was significantly lower in dairy manure (45%), but not in poultry (78%) or swine (73%) manures, relative to the Gainesville diet ( Figure 3 ).

Percent prepupation (mean ± SE, 1 n = 6) of black soldier fly larvae fed 7 kg of swine, dairy, or poultry manure or the Gainesville control diet [ 38 ] at 29 °C, 60% RH, and 16L:8D. Different letters (A, B) indicate significant differences between treatments (α = 0.05) and ANOVA, followed by Tukey’s HSD. 1 n = number of replicates per treatment.

3.4. Prepupal Weight

Prepupal weight did not differ significantly (F 3,16 = 0.5997; p = 0.6245) across the larval diets. No trial effect (F 1,16 = 3.5717; p = 0.0770) or treatment by trial interaction (F 3,16 = 0.0837; p = 0.9679) was observed. Larvae fed the Gainesville diet weighed approximately 173 mg, and those fed poultry, swine, and dairy weighed 163, 152, and 167 mg, respectively ( Figure 4 ).

Prepupal weight (mg) (mean ± SE, 1 n = 6) of black soldier fly larvae fed 7 kg of swine, dairy, or poultry manure or the Gainesville control diet [ 38 ] at 29 °C, 60% RH, and 16L:8D. Different letters (A) indicate significant differences between treatments (α = 0.05) and ANOVA, followed by Tukey’s HSD. 1 n = number of replicates per treatment.

4. Discussion

The results from this study demonstrate that diet can impact the production of BSF. Larvae fed the Gainesville diet [ 38 ] had the shortest development time (13 d) ( Figure 2 ), the highest survivorship (88%) ( Figure 3 ), and produced the heaviest prepupae (173 mg) ( Figure 4 ). In regard to those fed manure, variations in development time and survivorship were found across manure types. Although larval ( Figure 1 ) or prepupal weights ( Figure 2 ) did not differ across treatments ( p < 0.05), a longer development time (one to two days) was required for larvae to reach the prepupal stage, and fewer larvae survived (45%) when fed dairy manure. Similarly, in regard to the maximum weight, those fed swine manure reached their peak weight one day earlier than those fed dairy or poultry manures but weighed 25–50 mg less. These differences are important in respect to production efficiencies and bioconversion and may be explained by variations in the manure types.

Manure from different animals varies in chemical and physical compositions [ 39 ]. Poultry manure is typically higher in nutrients and lower in fiber than dairy manure [ 40 ], and these differences may explain differences in development and survivorship in the current study. Variation in development time and survivorship could translate to variation in production efficiency and bioconversion yields. Although prepupal weights were not significantly different across the treatments ( Figure 4 ), slower developments for those fed dairy manure ( Figure 2 ) and lower survivorship ( Figure 3 ) may have implications in higher costs of rearing (longer development time) and lower revenue (less yield). It is possible that those fed dairy manure were able to reach similar prepupal weights to those fed swine or poultry manures because the larvae were fed on the resource longer and were subject to reduced intraspecific competition because of high mortality. Additionally, BSF are thought to be generalist feeders, capable of digesting various wastes [ 15 , 17 , 41 ]. Compared to house flies, BSF have a larger arsenal of digestive enzymes that helps them acquire adequate nutrition from a variety of substrates to sustain their adult stage [ 41 ]. It is possible that the larval and prepupal weights did not differ significantly because BSF have such a wide range of digestive enzymes.

Previous studies that focus on BSF fed manure have been performed on a smaller scale (i.e., lower number of larvae per replicate) than the current study. Myers et al. [ 21 ] were the first to examine BSF development on dairy manure. Specifically, this study fed three hundred four-day-old larvae 27, 45, 54, or 70 g of dairy manure daily and found that the larval development to prepupation was significantly different ( p ≤ 0.05) between the lower feed ration and the other rations and lasted 26–30 d, which was up to two weeks longer than the findings from the current study (16 d). Survivorship to prepupation was not significantly different across the treatments for the aforementioned study (71–77%) but was greater than the survivorship found in the current study (45%). The prepupal weight was significantly different ( p ≤ 0.05) across the treatments in the small-scale dairy study (89–137 mg), and this was less than that observed in the current study (167 mg). However, when comparing the current study to another small-scale study that used a different manure type, such as poultry manure, impacts on the prepupal weight and development time were similar, but survivorship differed across the scales. For example, Lalander et al. [ 17 ], fed two hundred 10-d-old larvae poultry manure (40 mg DM/larva/d) and found prepupae weighed 165 mg, and those from the current study weighed 163 mg with the same development time to prepupation from the placement on manure (14 d). However, the current study found a lower survivorship (78% in the current study vs. 92% in Lalander et al. [ 17 ]). Yet, when we examine findings from our own small-scale study [ 29 ], which used larvae that were derived from the same colony as the current study, less time was needed for development in the small-scale study for those fed poultry manure (11 d vs. 14 d in the large-scale study), but more time was required in the small-scale study for those fed swine manure (17 d vs. 15 d in the current study), and larvae fed dairy manure required 16 d to develop, regardless of the scale. Although the percent prepupation was similar for those fed swine manure (84% vs. 73% in the current study), differences were more obvious for those fed dairy (93% vs. 45% in the current study) or poultry manures (78% vs. 95% in the current study). Additionally, differences in prepupal weight across the scales are apparent for swine, dairy, and poultry manures, as those in the small-scale study weighed 83, 99, and 114 mg compared to 152, 167, and 163 mg, respectively, in the current study.

Based on a comparison between this study and others conducted at a smaller scale, scale likely impacts the production of the BSF. Despite the fact that some aspects of the methodologies from some of the small-scale studies differed (such as rearing conditions and age of larvae at the initiation of the experiment) from the current study, there is overlap in methodologies among the studies that helps eliminate these factors from consideration as potential reasons for variation across the scales. For example, the rearing temperature for Myers et al. [ 21 ] (27 °C), and Lalander et al. [ 17 ] (28 °C) differed from the current study (29 °C); however, it is unlikely that this factor is largely responsible for differences across the scales, as Miranda et al. [ 29 ] used the same rearing temperature described by the current study, and differences in the development time, survivorship, and weight were found. The relative humidity should also not be considered influential, as most studies reared larvae at or around 60% RH. Additionally, although the age of the larvae at the initiation of the experiment differed between Lalander et al. [ 17 ] and the current study, it is also unlikely that this factor is responsible for the variations among the studies, because Myers et al. [ 21 ], Miranda et al. [ 29 ], and the current study conditioned larvae on the same diet (Gainesville diet [ 38 ]) for the same amount of time (four days) prior to the initiation of the experiment, and differences were found between these studies as well.

Interestingly, diet compositions across the manure types likely impacts the variation across the scales. For example, the development time did not differ for larvae fed dairy manure between Miranda et al. [ 29 ] and the current study, but differed for those fed poultry manure. Yet, when we compared the findings from Myers et al. [ 21 ] for dairy manure and those from Lalander et al. [ 17 ] for poultry manure to the current study, we saw that the opposite occurred, with delayed development reported by Myers et al. [ 21 ] for those fed dairy manure (26–30 d vs. 16 d) and the same development time as the current study for those fed poultry manure by Lalander et al. [ 17 ] (14 d). As previously discussed, manure types vary in chemical and physical properties and can vary within the same type, which may explain the differences observed between our study and previous small-scale studies. The development time is influenced by weight and survivorship, and so, the diet composition impacts those parameters as well. Furthermore, we find when comparing our study to Miranda et al. [ 29 ], which used larvae from the same colony with the same rearing conditions, and manure collected from the same facilities as the current study; differences across the manure types for development time, prepupal weight, and survivorship do not follow the same pattern across the scales. For example, for development time, the results were similar regardless of the scale, with swine and dairy not significantly different ( p ≤ 0.05) from each other but significantly different from poultry manure in either study. Larvae from the small-scale experiment developed faster on poultry manure (by three days) than those in the large-scale study, and these findings correlate with those from Barragán-Fonseca et al. [ 26 ], which found that lower densities and higher nutrient concentrations accelerated development. However, the pattern of differences across manure types for prepupal weights differed across the scales, with more pronounced differences among the manure types at the smaller scale compared to the larger scale. Specifically, larvae fed swine manure in the small-scale study were significantly different ( p ≤ 0.0001) in regard to prepupal weights from those fed poultry manure, but larvae fed swine, dairy, or poultry manure in the large-scale study were not significantly different ( p = 0.0624). Barragán-Fonseca et al. [ 26 ] found that the weights increased with the increased nutrient concentrations, and this was the case for the small-scale study but not for the large-scale study, as those fed dairy manure weighed more (167 mg) than those fed poultry (163 mg) or swine (152 mg). Although dairy manure is generally considered a lower-quality manure compared to swine or poultry manure, higher prepupal weights for larvae fed dairy manure may be explained by the lower survivorship, as previously discussed. Finally, the pattern of differences across manure types for percent of pupation differed across the scales, with more pronounced differences on the larger scale ( p ≤ 0.0001) than in the smaller scale ( p = 0.0004), but the findings from our studies do not agree with Barragán-Fonseca et al. [ 26 ] that survivorship increases with higher densities, as fewer individuals were produced from the large-scale study (45–78% survivorship) compared to the small-scale study (84–95% survivorship); however, our findings do agree that survivorship increases with increasing nutrient concentrations. The extent of the impact of diet compositions on differences across the scales is poorly understood due to a lack of large-scale studies; therefore, small-scale studies should include a large-scale component when possible.

Other factors known to influence BSF development are moisture [ 28 , 42 , 43 ], pH [ 44 , 45 ], species strain [ 46 ], and size of the rearing container [ 47 ]. However, because most studies are conducted with a few-hundred larvae, the impact of these factors is not necessarily the same at higher scales. It may thus be difficult for individuals interested in mass-producing BSF to extrapolate and apply information with expectations similar to those reported from studies that use methods that differ from industrial standards. It should be noted that the authors of this paper have also performed small-scale studies [ 28 , 29 ] but recognize that the outcomes of these studies may differ at a larger scale. Additionally, there are facilities that produce larvae at higher densities than 10,000 larvae and provide larvae more than 7 kg of diet, and so it is possible that the results from this study may not translate on a higher production scale. For these reasons, future studies should investigate BSF life-history parameters at larger scales than the current study.

5. Conclusions

The current study shows differences in the development time and survivorship for larvae fed different manure types. Although no significant difference was found across the manure types for prepupal weight, those provided dairy manure took one to two days longer to develop, with fewer individuals surviving to the prepupal stage (45% vs. >70%) when compared to those provided swine or poultry manures. Additionally, this study highlights the potential differences likely to exist across the production scales and urges future studies to perform their work on larger scales to advance the industrialization of BSF.

Acknowledgments

The authors wish to thank Melanic Osegueda and Sydney Busch for their assistance in maintaining the fly colonies as well as their efforts during the experiment. We also would like to thank Brittny Jones, Zanthé Bruce, and Aline Malawey for their efforts maintaining the BSF colony.

Author Contributions

Conceptualization, C.D.M. and J.K.T.; investigation, C.D.M; methodology, C.D.M. and J.K.T.; supervision, J.K.T.; writing—original draft preparation, C.D.M.; and writing—review and editing, C.D.M., J.A.C., and J.K.T. All authors have read and agreed to the published version of the manuscript.

The F.L.I.E.S. Facility at Texas A&M University would like to thank Fluker Farms (Port Allen, LA, USA) and EVO Conversion Systems, LLC (College Station, TX, USA) for their partial financial support of this project.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

- Search Menu

- Sign in through your institution

- Computer Science

- Earth Sciences

- Information Science

- Life Sciences

- Materials Science

- Science Policy

- Advance Access

- Special Topics

- Author Guidelines

- Submission Site

- Open Access Options

- Self-Archiving Policy

- Reasons to submit

- About National Science Review

- Editorial Board

- Advertising and Corporate Services

- Journals Career Network

- Dispatch Dates

- Journals on Oxford Academic

- Books on Oxford Academic

Article Contents

Introduction, structure and definition of graphene, basic properties and applications proposed in laboratory-scale research, mass production of graphene materials, some commercial applications of graphene materials on the market, summary and outlook, acknowledgement, declarations.

- < Previous

Mass production and industrial applications of graphene materials

- Article contents

- Figures & tables

- Supplementary Data

Yanwu Zhu, Hengxing Ji, Hui-Ming Cheng, Rodney S Ruoff, Mass production and industrial applications of graphene materials, National Science Review , Volume 5, Issue 1, January 2018, Pages 90–101, https://doi.org/10.1093/nsr/nwx055

- Permissions Icon Permissions

Graphene is considered a promising material for industrial application based on the intensive laboratory-scale research in the fields of physics, chemistry, materials science and engineering, and biology over the last decade. Many companies have thus started to pursue graphene materials on a scale of tons (for the flake material) or hundreds of thousands of square meters (for the film material) for industrial applications. Though the graphene industry is still in its early stages, very significant progress in mass production and certain industrial applications has become obvious. In this report, we aim to give a brief review of the mass production of graphene materials for some industrial applications and summarize some features or challenges for graphene in the marketplace.

Graphene has attracted attention worldwide and is considered a promising material for industrial applications. Before the exfoliation of graphene with Scotch tape was reported in 2004 [ 1 ], several groups had exfoliated graphite to thin platelets [ 2 , 3 ], and identified ‘single-layer graphite’ on noble metal surfaces as grown by chemical vapor deposition (CVD) [ 4 ]. Properties and applications of graphene have been the subject of studies by the physics, chemistry, materials science, biology, biomedical and energy research communities, among others [ 5–7 ]. The 2010 Nobel Prize in Physics was awarded for “groundbreaking experiments regarding the 2D material, graphene” [ 1 ]. Around 2009, several research groups achieved breakthroughs in developing macro-scale CVD synthesis of graphene [ 8–10 ]. Earlier research on graphite oxide [ 6 , 11 ], its exfoliation in water and manipulation of the chemical properties of the resulting ‘graphene oxide’ sheets led to breakthroughs in its use in conductive polymer composites at a low loading level [ 12 ], to the generation of ‘paper-like’ films [ 13 ], and then later to their use as an electrode material in supercapacitors, their first use in electrical energy storage [ 14 ] and in many other applications [ 5 , 6 , 15–20 ]. These laboratory-scale pioneering results triggered intense interest in the mass production and industrial applications of graphene materials.

Many start-up companies as well as existing industrial enterprises have thus pursued graphene materials on a scale of tons (for the flake material from either graphite oxide or graphite itself), or hundreds of thousands of square meters (for graphene films made by CVD). They and other companies have also started to develop graphene-related products. In this report, we aim to give a brief summary of the mass production of graphene materials for some industrial applications. It is not our intent to exhaustively cover every application. We first define what is meant by graphene and ‘graphene-like’, briefly outline some of the basic properties of graphene and then introduce actual applications and some commercial products on the current market.

Graphene by definition is a single layer of carbon atoms organized in a 2D, atom-thick, ‘honeycomb’ lattice by sp 2 hybridized C–C bonds between two adjacent carbon atoms (IUPAC, 1995) [ 21 ]. It is worth noting, however, that the term is used more liberally to also include materials that have multi-layer graphene or few-layer graphene, that is, more than one layer of graphene stacked on top of each other. Various microscopy techniques have allowed observation of the atomic lattice of suspended graphene, as well as defects such as adatoms, vacancies, holes and so on [ 22 ]. In graphene samples the atom-thick layer is mechanically compliant and so sheets (also called platelets) are often wrinkled and/or crumpled, and, in many applications, the carbon atoms in the basal plane are functionalized with various chemical groups to enable the commercial application of interest. That is, almost all ‘graphene materials’ are different from the idealized 2D ‘graphene structure’ as proposed in 1947 [ 23 ]. What is now referred to as graphene was originally obtained by surface scientists by CVD on a variety of substrates; for example, see the perspective by Ruoff [ 24 ]. Thus with reference to commercial products, it should be appreciated that ‘graphene’ or ‘graphene-like’ refers to atom-thick layers that might be chemically functionalized and contain various sorts of defects, and are used in real applications.

Here we briefly summarize the basic properties and potential applications of graphene, and note that several review articles are provided here [ 15 , 25–27 ].

A perfect graphene sheet is a zero-bandgap semiconductor with a cone-like band structure near the Dirac point that displays an ambipolar electric field effect in which charge carriers (electrons or holes) show a linear dispersion relationship in concentrations of up to 10 13 cm −2 [ 1 , 5 ]. In addition, graphene has a half-integer quantum Hall effect (QHE) for both electron and hole carriers and also a high electron mobility of 1.5 × 10 4 cm 2 ·V −1 ·s −1 at room temperature, which is nearly independent of temperature between 10 K and 100 K [ 28–31 ]. Each additional graphene layer adds an optical absorption of ∼2.3% in a broad wavelength ranging from ultraviolet to near infrared, as a consequence of graphene's electronic structure [ 32 ]. The absorption becomes saturated when the input optical intensity is above a threshold value, leading to a nonlinear optical behavior [ 33 , 34 ]. The thermal conductivity of suspended graphene was stated to be in the range of ∼(4.84 ± 0.44) × 10 3 to (5.30 ± 0.48) × 10 3 W/mK at room temperature from Raman measurements [ 35 ], and it remains as high as about 600 W/mK when graphene is supported on SiO 2 , exceeding the value for metals such as copper and conventional thin-film electronic materials [ 36 ]. With a Young's modulus of 1060 GPa, and an intrinsic strength of 130 GPa, a free-standing graphene membrane has a breaking strength of 42 N/m, much stronger than steel's if one assumes a similar thickness [ 37 , 38 ]. Graphene is impermeable to all atoms and molecules under ambient conditions [ 39 , 40 ]. Hydrogen, the smallest atom, is predicted to take billions of years to penetrate graphene [ 41 , 42 ]. Monolayers of graphene, however, are permeable to thermal protons under ambient conditions, whereas no proton transport has been detected for bilayer graphene [ 43 ]. Although graphene is structurally stable and moderately chemically inert, chemical processing such as oxidization or fluorination may break the carbon bonding and introduce functional groups in graphene, thus bringing more variety in the properties and functions [ 44 , 45 ]. When functional groups are covalently attached to graphene, its highly extended pi electron cloud is disrupted, changing its electronic properties [ 46 ].

Graphene has been considered a good candidate for many applications, ranging from electronics [ 47 , 48 ], photonics [ 17 , 49 , 50 ], energy generation and storage [ 51–53 ], thermal management [ 54 , 55 ] and functional materials [ 12 , 56 ] to bio-applications [ 57 , 58 ], and many others. It is worth noting that potential applications of graphene can depend on the morphology and structure, which are mostly determined by the production methods and subsequent processing techniques. In the following, the techniques for preparing graphene, especially by mass production, are reviewed.

Many reviews have been published on the preparation of graphene materials on a laboratory scale [ 16 , 25 , 59 , 60 ], and here the focus is on the industrial-scale production of graphene materials and related issues. The techniques for the mass production must be able to meet the needs for the scale of testing in industry, which is typically a kilogram of powder or suspension containing graphene flakes (typically of micrometer scale), or a thousand pieces for continuous graphene films (usually larger than millimeter size). Considering the following factors: (i) the demands of attaining the desired properties and form/morphology for target graphene products; (ii) the quality and applications of the graphene materials; (iii) the scalability from laboratory to industry; and (iv) the stability and controllability of manufacturing, we note that the current production techniques used in industry are mainly the exfoliation of graphite, exfoliation/reduction of graphite oxide and CVD.

Direct liquid-phase exfoliation of graphite

Graphite is cheap and abundant, and the key to its exfoliation is overcoming the van der Waals interaction between graphene layers while maintaining the size of the graphene platelets. In addition to the energy input such as sonication, stirring, shearing forces, ball milling and so on, proper selection of solvents and surfactants is helpful in improving the yield of graphene platelets from graphite [ 61–63 ]. More importantly, the graphene platelets that are obtained by mechanical exfoliation potentially maintain the conjugated structure that exists in graphite, and may thus have good electrical conductivity and other properties predicted or measured for graphene. Since exfoliation is usually carried out in a solvent, its removal may cause severe restacking of the graphene platelets due to the van der Waals forces and (if present) capillary forces between them upon drying. Thus, the typical graphene products obtained from the direct exfoliation of graphite are suspensions or slurries, and the presence of solvents and other additives needs to be considered when the graphene suspensions are later used.

We have identified several companies that have reported producing graphene-containing suspensions/slurries based on the exfoliation of graphite (or similar precursors such as expanded graphite). Applied Graphene Materials plc in the UK was set up in 2010 and is advertising graphene dispersions on their website. Several companies (e.g. Ningbo MORSH, Qingdao Haoxin New Energy Technology, Dongguan SuperC Technology, Deyang Carbonene Technology) in China claim to use ‘physical exfoliation’ to produce graphene materials on the scale of hundreds to thousands of tons (of suspensions or slurries). For example, Dongguan SuperC Technology Ltd has announced a production capability of 10 000 tons of graphene suspension per year. As the exfoliation of graphite typically leads to a wide distribution of number of layers for the flakes, the suspensions have to be subjected to harsh separation processing to obtain graphene with a certain number of layers; chemical additives such as surfactants are often needed to keep the suspension stable for a long time. With better control of the thickness uniformity and stability, graphene materials from the direct exfoliation of graphite may have promise for use in paints and inks, as conducting additives in battery electrodes, as conducting fillers in composites and so on.

Oxidization of graphite and the subsequent exfoliation and/or reduction

Another well-known approach to exfoliate ‘graphitic layers’ is through oxidative intercalation using oxidizing agents such as sulfuric and nitric acids, and potassium permanganate. The oxygen functional groups in oxidized graphite are prevalent in the individual layers and thus sp 3 -hybridized carbon atoms are prevalent in the sp 2 -hybridized carbon network of the layers in graphite, leading to the product called graphite oxide [ 11 , 64–66 ]. Graphite oxide was first prepared by Brodie about 150 years ago [ 67 ], and was used by Boehm et al. for the preparation of thin graphene-containing platelets in 1962 [ 68 ]. With the increased interlayer distance including that due to adsorbed water, which is present as interlamellar (interlayer) H 2 O molecules that are bonded both to themselves and to the epoxide and hydroxyl functional groups on the layers, a small energy input such as stirring or bath-ultrasonication could break the interaction between oxidized graphene layers and yield dispersed individual layers: ‘graphene oxide’. A subsequent process to eliminate the majority of the oxygen functional groups, often called reduction but sometimes referred to as deoxygenation, can be used to partially recover the conjugated structure and electrical conductivity. Many approaches, e.g. using reducing regents to react with the oxygen functional groups, or ‘burning’ off the oxygen with thermal/microwave heating, irradiation, plasma/ion bombardment, have been developed to reduce graphite oxide or graphene oxide in the past decade [ 69–73 ]. Ruoff's group has demonstrated the impressive properties and potential applications of ‘paper-like’ materials made from graphene oxide and composites containing reduced graphene oxide mixed with polymer [ 12 , 13 ].

Products derived from graphite oxide include reduced graphite oxide and reduced graphene oxide powders as well as suspensions of graphene oxide made by exfoliating graphite oxide in solvents, and suspensions of reduced graphene oxide. The detailed morphology, structure and chemical components of the graphite-oxide-derived products are sensitive to the processing parameters and the equipment used, because the manufacturing processes involve chemistry and chemical engineering. This has several implications for production of ‘graphene’ based on graphite oxide. First, since the products are highly dependent on the manufacturing technique, products made by different companies may be very different in terms of physical morphology and chemical properties, although the companies may use similar techniques for manufacturing the graphite oxide. Second, due to the different and complicated morphological, structural and chemical features of graphene materials based on graphite oxide, the use (application) of such products often needs to be coordinated with the manufacturer. The complex relationship between the graphene materials and their applications may mean that most of the products from graphite oxide must be ‘custom-built’ and are definitely not ‘one type fits all’ applications. In addition, standardization for future industrial use will be difficult (but, of course, still important) because of differences in raw materials, subtle differences in manufacturing and the difficulties in its control, and the role of graphene materials in their final applications. Oxidation of graphite has been used by a few start-up companies to produce graphene materials, because the chemical processing is scalable. The Sixth Element Materials Technology (Changzhou) Co. Ltd announced a production capability of 100 tons of graphene oxide per year in 2012 (Fig. 1 a). Yan Qu, CEO of The Sixth Element notes, “… we are surprised by the wide range of applications of graphite-oxide-derived materials, from thermal dissipation films, to composites, and a conducting additive in the electrode of Li-ion batteries.” Further understanding of the chemistry during the materials processing of graphite oxide and of applications will be helpful in achieving products and performance with better stability and controllability.

(a) Graphene powder production line in The Sixth Element Materials Technology Co. Ltd. (b) Graphene film production line of Wuxi Graphene Films Co. Ltd. All photos are used with permission of copyright.

Chemical vapor deposition (CVD)

The CVD technique used in producing industrial graphene films is mainly based on the research published in Science in 2009 by Ruoff's group [ 74 ], namely, the growth of graphene on Cu foil from methane and hydrogen. In 2010, Hong, who cooperated with Samsung Tech., demonstrated a prototype manufacturing line that was able to produce rectangular graphene films 30 inches along a diagonal [ 75 ]. The CVD production of graphene typically has four steps: (i) synthesis of graphene films on metal foils such as Cu foils by CVD, (ii) removal of the metal, (iii) transfer of the graphene films onto a desired substrate, and (iv) doping the graphene film for reduced sheet resistance if needed. The CVD process can be carried out at either a low pressure (∼0.1 Torr) or at ambient pressure [ 76 ] and both have been applied in pilot lines for the industrial production of graphene. Currently, removing the Cu by chemical etching has been intensively used for graphene production. However, Cu accounts for more than 50% of the cost. There are several other potential methods available on a laboratory scale, e.g. electrochemical bubbling transfer [ 77 ] and electrostatic-force-assisted transfer [ 78 ], and these or other methods might be useful in the future on the industrial scale. To avoid breaking the graphene during transfer, it is protected with a covering polymer film that is removed after the graphene film has been transferred onto the target substrate. Alternatively an adhesive can be applied between the target substrate and the graphene on Cu, and the subsequent Cu etching leaves graphene on the target substrate with the adhesive layer in between. Both techniques are currently used for CVD graphene production in industry. To reduce the sheet resistance of the as-prepared CVD graphene to below 1000 ohm/sq, doping is often required, especially for the use of graphene in applications such as transparent conductors. The most popular doping agents used in industry are inorganic salts, for example, Fe(NO) 3 , HNO 3 and AuCl, because of their processability, stability and price.

Among companies actively involved in CVD graphene production are 2D Carbon (Changzhou) Tech. Inc. Ltd, Wuxi Graphene Films Co. Ltd and Chongqing Graphene Technology Co. Ltd in China; Graphene Square Inc. in Korea; Graphenea Inc. in Spain; BGT Materials Ltd in the UK; and Graphene Laboratories Inc. in the USA (one example is shown in Fig. 1 b). Graphene Square provides graphene films with a size of up to 8 × 8 cm 2 that are produced on Cu foil and then transferred onto a SiO 2 /Si wafer or quartz glass. Graphene films on polyethylene terephthalate (PET) with a size of 100 × 100 cm 2 are available to custom order. Changzhou 2D Carbon, Wuxi Graphene Films and Chongqing Graphene Technology have announced that their annual production capacities for graphene film on Cu foil are 150 000, 100 000 and 1 000 000 m 2 , respectively, and all are able to provide graphene films with sizes of up to 300 × 30 cm 2 on Cu foil or PET film. BGT Materials provides graphene film on SiO 2 /Si or PET with sizes in the range of 1 × 1 to 20 × 25 cm 2 . In January 2017, Graphenea announced an annual production capability of 7 000 wafers of CVD graphene with a wafer size of up to 8 inches. Graphene Laboratories are able to provide graphene on PET with sizes of <20 × 20 cm 2 . This information was obtained from the websites of each company.

For the further development of the CVD graphene industry, achieving (i) a wafer-scale size (or larger) of single crystal graphene and (ii) its nondestructive and clean transfer from the Cu foil (or other growth substrate if others are found) to a dielectric substrate (or other, arbitrary substrate) that satisfies the needs of industrial applications, e.g. fast processing, low price, high reliability and automatic control, are relevant. (Of course, there may be applications where polycrystalline graphene will serve sufficiently well and if it is less expensive than single-crystal material, of course it will be used.) Other challenges such as the controllable preparation of multi-layer graphene on metals and the direct growth of graphene on dielectric substrates with a quality comparable to that on Cu should also be targeted. An example is the recently reported growth of graphene on glass [ 79 , 80 ].