MBA Knowledge Base

Business • Management • Technology

Home » Management Case Studies » Case Study: Quality Management System at Coca Cola Company

Case Study: Quality Management System at Coca Cola Company

Coca Cola’s history can be traced back to a man called Asa Candler, who bought a specific formula from a pharmacist named Smith Pemberton. Two years later, Asa founded his business and started production of soft drinks based on the formula he had bought. From then, the company grew to become the biggest producers of soft drinks with more than five hundred brands sold and consumed in more than two hundred nations worldwide.

Although the company is said to be the biggest bottler of soft drinks, they do not bottle much. Instead, Coca Cola Company manufactures a syrup concentrate, which is bought by bottlers all over the world. This distribution system ensures the soft drink is bottled by these smaller firms according to the company’s standards and guidelines. Although this franchised method of distribution is the primary method of distribution, the mother company has a key bottler in America, Coca Cola Refreshments.

In addition to soft drinks, which are Coca Cola’s main products, the company also produces diet soft drinks. These are variations of the original soft drinks with improvements in nutritional value, and reductions in sugar content. Saccharin replaced industrial sugar in 1963 so that the drinks could appeal to health-conscious consumers. A major cause for concern was the inter product competition which saw some sales dwindle in some products in favor of others.

Coca Cola started diversifying its products during the First World War when ‘Fanta’ was introduced. During World War 1, the heads of Coca Cola in Nazi Germany decided to establish a new soft drink into the market. During the ongoing war, America’s promotion in Germany was not acceptable. Therefore, he decided to use a new name and ‘Fanta’ was born. The creation was successful and production continued even after the war. ‘Sprite’ followed soon after.

In the 1990’s, health concerns among consumers of soft drinks forced their manufactures to consider altering the energy content of these products. ‘Minute Maid’ Juices, ‘PowerAde’ sports drinks, and a few flavored teas variants were Coca Cola’s initial reactions to this new interest. Although most of these new products were well received, some did not perform as well. An example of such was Coca Cola classic, dubbed C2.

Coca Cola Company has been a successful company for more than a century. This can be attributed partly to the nature of its products since soft drinks will always appeal to people. In addition to this, Coca Cola has one of the best commercial and public relations programs in the world. The company’s products can be found on adverts in virtually every corner of the globe. This success has led to its support for a wide range of sporting activities. Soccer, baseball, ice hockey, athletics and basketball are some of these sports, where Coca Cola is involved

The Quality Management System at Coca Cola

It is very important that each product that Coca Cola produces is of a high quality standard to ensure that each product is exactly the same. This is important as the company wants to meet with customer requirements and expectations. With the brand having such a global presence, it is vital that these checks are continually consistent. The standardized bottle of Coca Cola has elements that need to be checked whilst on the production line to make sure that a high quality is being met. The most common checks include ingredients, packaging and distribution. Much of the testing being taken place is during the production process, as machines and a small team of employees monitor progress. It is the responsibility of all of Coca Colas staff to check quality from hygiene operators to product and packaging quality. This shows that these constant checks require staff to be on the lookout for problems and take responsibility for this, to ensure maintained quality.

Coca-cola uses inspection throughout its production process, especially in the testing of the Coca-Cola formula to ensure that each product meets specific requirements. Inspection is normally referred to as the sampling of a product after production in order to take corrective action to maintain the quality of products. Coca-Cola has incorporated this method into their organisational structure as it has the ability of eliminating mistakes and maintaining high quality standards, thus reducing the chance of product recall. It is also easy to implement and is cost effective.

Coca-cola uses both Quality Control (QC) and Quality Assurance (QA) throughout its production process. QC mainly focuses on the production line itself, whereas QA focuses on its entire operations process and related functions, addressing potential problems very quickly. In QC and QA, state of the art computers check all aspects of the production process, maintaining consistency and quality by checking the consistency of the formula, the creation of the bottle (blowing), fill levels of each bottle, labeling of each bottle, overall increasing the speed of production and quality checks, which ensures that product demands are met. QC and QA helps reduce the risk of defective products reaching a customer; problems are found and resolved in the production process, for example, bottles that are considered to be defective are placed in a waiting area for inspection. QA also focuses on the quality of supplied goods to Coca-cola, for example sugar, which is supplied by Tate and Lyle. Coca-cola informs that they have never had a problem with their suppliers. QA can also involve the training of staff ensuring that employees understand how to operate machinery. Coca-Cola ensures that all members of staff receive training prior to their employment, so that employees can operate machinery efficiently. Machinery is also under constant maintenance, which requires highly skilled engineers to fix problems, and help Coca-cola maintain high outputs.

Every bottle is also checked that it is at the correct fill level and has the correct label. This is done by a computer which every bottle passes through during the production process. Any faulty products are taken off the main production line. Should the quality control measures find any errors, the production line is frozen up to the last good check that was made. The Coca Cola bottling plant also checks the utilization level of each production line using a scorecard system. This shows the percentage of the line that is being utilized and allows managers to increase the production levels of a line if necessary.

Coca-Cola also uses Total Quality Management (TQM) , which involves the management of quality at every level of the organisation , including; suppliers, production, customers etc. This allows Coca-cola to retain/regain competitiveness to achieve increased customer satisfaction . Coca-cola uses this method to continuously improve the quality of their products. Teamwork is very important and Coca-cola ensures that every member of staff is involved in the production process, meaning that each employee understands their job/roles, thus improving morale and motivation , overall increasing productivity. TQM practices can also increase customer involvement as many organisations, including Coca-Cola relish the opportunity to receive feedback and information from their consumers. Overall, reducing waste and costs, provides Coca-cola with a competitive advantage .

The Production Process

Before production starts on the line cleaning quality tasks are performed to rinse internal pipelines, machines and equipment. This is often performed during a switch over of lines for example, changing Coke to Diet Coke to ensure that the taste is the same. This quality check is performed for both hygiene purposes and product quality. When these checks are performed the production process can begin.

Coca Cola uses a database system called Questar which enables them to perform checks on the line. For example, all materials are coded and each line is issued with a bill of materials before the process starts. This ensures that the correct materials are put on the line. This is a check that is designed to eliminate problems on the production line and is audited regularly. Without this system, product quality wouldn’t be assessed at this high level. Other quality checks on the line include packaging and carbonation which is monitored by an operator who notes down the values to ensure they are meeting standards.

To test product quality further lab technicians carry out over 2000 spot checks a day to ensure quality and consistency. This process can be prior to production or during production which can involve taking a sample of bottles off the production line. Quality tests include, the CO2 and sugar values, micro testing, packaging quality and cap tightness. These tests are designed so that total quality management ideas can be put forward. For example, one way in which Coca Cola has improved their production process is during the wrapping stage at the end of the line. The machine performed revolutions around the products wrapping it in plastic until the contents were secure. One initiative they adopted meant that one less revolution was needed. This idea however, did not impact on the quality of the packaging or the actual product therefore saving large amounts of money on packaging costs. This change has been beneficial to the organisation. Continuous improvement can also be used to adhere to environmental and social principles which the company has the responsibility to abide by. Continuous Improvement methods are sometimes easy to identify but could lead to a big changes within the organisation. The idea of continuous improvement is to reveal opportunities which could change the way something is performed. Any sources of waste, scrap or rework are potential projects which can be improved.

The successfulness of this system can be measured by assessing the consistency of the product quality. Coca Cola say that ‘Our Company’s Global Product Quality Index rating has consistently reached averages near 94 since 2007, with a 94.3 in 2010, while our Company Global Package Quality Index has steadily increased since 2007 to a 92.6 rating in 2010, our highest value to date’. This is an obvious indication this quality system is working well throughout the organisation. This increase of the index shows that the consistency of the products is being recognized by consumers.

Related posts:

- Case Study: The Coca-Cola Company Struggles with Ethical Crisis

- Case Study: Analysis of the Ethical Behavior of Coca Cola

- Case Study of Burger King: Achieving Competitive Advantage through Quality Management

- SWOT Analysis of Coca Cola

- Case Study: Marketing Strategy of Walt Disney Company

- Case Study of Papa John’s: Quality as a Core Business Strategy

- Case Study: Johnson & Johnson Company Analysis

- Case Study: Inventory Management Practices at Walmart

- Case Study: Analysis of Performance Management at British Petroleum

- Total Quality Management And Continuous Quality Improvement

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Implementation of Total Quality Management (TQM): Toyota Case Study

Introduction, implementation of tqm in toyota, tqm practices in toyota, benefits of tqm in toyota, examples of tqm in toyota, toyota quality management, toyota tqm implementation challenges.

The Toyota Corporation case study report is based on the implementation of total quality management (TQM) meant to improve the overall performance and operations of this automobile company. TQM involves the application of quality management standards to all elements of the business.

It requires that quality management standards be applied in all branches and at all levels of the organization. The characteristic of Toyota Corporation going through the total quality process is unambiguous and clear.

Toyota has limited interdepartmental barriers, excellent customer and supplier relations, spares time to be spent on training, and the recognition that quality is realized through offering excellent products as well as the quality of the entire firm, including personnel, finance, sales, and other functions.

The top management at Toyota Corporation has the responsibility for quality rather than the employees, and it is their role to provide commitment, support, and leadership to the human and technical processes (Kanji & Asher, 1996).

Whereas the TQM initiative is to succeed, the management has to foster the participation of Toyota Corporation workers in quality improvement and create a quality culture by altering attitudes and perceptions towards quality.

This research report assesses the implementation of TQM and how Toyota manages quality in all organization management systems while focusing on manufacturing quality. The report evaluates the organization management elements required when implementing TQM, identifies, and investigates the challenges facing Quality Managers or Executives in implementing Quality Management Systems.

In order to implement TQM, Toyota corporations focused on the following phases:

- The company extended the management responsibility past the instantaneous services and products

- Toyota examined how consumers applied the products generated, and this enabled the company to develop and improve its commodities

- Toyota focused on the insubstantial impacts on the procedures as well as how such effects could be minimized through optimization

- Toyota focused on the kaizen (incessant process development) in order to ensure that all procedures are measurable, repeatable, and visible.

The commitment from business executives is one of the key TQM implementation principles that make an organization successful. In fact, the organizational commitment present in the senior organizational staff ranges from top to lower administration. These occur through self-driven motives, motivation, and employee empowerment. Total Quality Management becomes achievable at Toyota by setting up the mission and vision statements, objectives, and organizational goals.

In addition, the TQM is achievable via the course of active participation in organizational follow-up actions. These actions denote the entire activities needed and involved during the implementation of the set-out ideologies of the organization. From Toyota Corporation’s report, TQM has been successful through the commitment of executive management and the organizational workforce (Toyota Motor Corporation, 2012).

Through inventory and half the bottlenecks at half cost and time, the adopters of TMS (Toyota Management System) are authorized to manufacture twice above the normal production. To manage the quality in all organizational management systems, the Toyota Production System incorporates different modernisms like strategy or Hoshin Kanri use, overall value supervision, and just-in-time assembly.

The amalgamation of these innovations enables Toyota to have a strong competitive advantage despite the fact that Toyota never originated from all of them. The 1914 Henry Ford invention relied on the just-in-time production model. The Ford system of production, from a grand perspective, warrants massive production, thus quality (Toyota Motor Corporation, 2012).

Kanji and Asher (1996) claim that to manage the minute set of production necessitated by the splintered and small post-war marketplaces, the JIT system focuses on the motion and elimination of waste materials. This reduces crave for work-in-process inventory by wrapping up the long production lines. Toyota Corp wraps the production lines into slashed change-over times, a multi-trained workforce that runs manifold machines, and new-fangled cells into a U shape.

When supplementing the just-in-cells, the system of kanban is employed by the Toyota Corporation to connect the cells that are unable to integrate physically. Equally, the system helps Toyota integrate with other external companies, consumers, and suppliers.

The TQM and the creativity of Toyota proprietors both support the quality at the source. The rectification and discovery of the production problems require the executives to be committed. At the forefront of Toyota operations, the managers integrate a number of forms of operational quality checks to ensure quality management at all levels.

The uninterrupted tests help the Toyota workforce engaging in the assembly course to scrutinize the value of apparatus, implements, and resources utilized in fabrication. The checks help in the scrutiny of the previously performed tasks by other workers. However, the corporation’s own test enables the workers to revise their personal advances in the assembly course.

The Toyota process owners set up the mistake-proofing (Poka-yoke) procedures and devices to capture the awareness of management and involuntarily correct and surface the augmenting problems. This is essential for the critical production circumstances and steps that prove impractical and tricky for Toyota employees to inspect.

Nevertheless, the policy deployment system decentralizes the process of decision-making at Toyota. This context of implementing Total Quality Management originates from Hoshin Kanri’s management by objective (MBO).

This aspect becomes more advantageous to Toyota when dealing with quality management. The system initially puts into practice the coordinated approach and provides a clear structure for the suppliers, producers, and consumers through inter-organizational cost administration. Moreover, Toyota executives can solve the concurrent delivery, cost, and quality bottlenecks, thus replacing and increasing the relatively slow accounting management mechanisms.

Customer focus that leads to the desired customer satisfaction at Toyota Company is one of the major success factors in TQM implementation. For every business to grow, it should have understanding, reliable, and trustworthy customers. The principle of customer satisfaction and focus has been the most presently well-thought-out aspect of Toyota’s manufacturing quality.

The TQM may characteristically involve total business focus towards meeting and exceeding customers’ expectations and requirements by considering their personal interests. The mission of improving and achieving customer satisfaction ought to stream from customer focus.

Thus, when focusing on manufacturing quality, this aspect enhances TQM implementation. The first priorities at Toyota are community satisfaction, employees, owners, consumers, and mission. The diverse consumer-related features from liberty. The concern to care is eminent in Toyota Corporation during manufacturing.

Toyota has three basic perspectives of TQM that are customer-oriented. These are based on its manufacturing process traced back to the 1950s. The strategies towards achieving quality manufacturing, planning, and having a culture towards quality accomplishment are paramount for TQM implementation to remain successful. To enhance and maintain quality through strategic planning schemes, all managers and employers must remain effectively driven.

This involves training workers on principles concerning quality culture and achievement. Scheduling and planning are analytical applications at Toyota Company that purposes in assessing customer demand, material availability, and plant capacity during manufacturing.

The Toyota Corporation has considerable approaches that rank it among the successful and renowned implementers of TQM. From the inherent and designed structure of Toyota, it becomes feasible to comprehend why quality manufacturing is gradually becoming effective. The inspection department is responsible for taking corrective measures, salvaging, and sorting the desired manufactured product or service quality.

The Toyota Corporation also has a quality control system that is involved in determining quality policies, reviewing statistics, and establishing quality manuals or presentation data. Furthermore, quality assurance is one of the integral principles in quality implementation that is practically present at Toyota. The quality assurance and quality inspectors throughout the Toyota Company structure also manage research and development concerning the quality of manufactured products and services.

The Toyota production and operations management system is similarly dubbed as the managerial system. In fact, in this corporation, operational management is also referred to as the production process, production management, or operations (Chary, 2009). These simply incorporate the actual production and delivery of products.

The managerial system involves product design and the associated product process, planning and implementing production, as well as acquiring and organizing resources. With this broad scope, the production and operation managers have a fundamental role to play in the company’s ability to reach the TQM implementation goals and objectives.

The Toyota Corporation operations managers are required to be conversant and familiar with the TQM implementation concepts and issues that surround this functional area. Toyota’s operation management system is focused on fulfilling the requirements of the customers.

The corporation realizes this by offering loyal and express commodities at logical fees and assisting dealers in progressing commodities proffered. As Slack et al. (2009) observed, the basic performance objectives, which pertain to all the Toyota’s operations, include quality, speed, flexibility, dependability, and cost. Toyota Company has been successful in meeting these objectives through its production and operation functions.

Over several decades, Toyota’s operational processes and management systems were streamlined, resulting in the popularly known Toyota Production System. Although the system had been extensively researched, many companies, such as Nissan, experienced difficulties in replicating TPS.

The TPS was conceived when the company realized that producing massive quantities from limited product lines and ensuring large components to achieve maximum economies of scale led to flaws. Its major objectives were to reduce cost, eliminate waste, and respond to the changing needs of the customers. The initial feature of this system was set-up time reduction, and this forms the basis of TQM implementation.

At Toyota Corporation, quality is considered as acting responsibly through the provision of blunder-gratis products that please the target clientele. Toyota vehicles are among the leading brands in customer satisfaction. Due to good quality, its success has kept growing, and in 2012, the company was the best worldwide. Moreover, Toyota has been keen on producing quality vehicles via the utilization of various technologies that improve the performance of the vehicles.

While implementing TQM, Toyota perceives speed as a key element. In this case, speed objective means doing things fast in order to reduce the time spent between ordering and availing the product to the customer.

The TPS method during processing concentrates on reducing intricacy via the use of minute and uncomplicated machinery that is elastic and full-bodied. The company’s human resources and managers are fond of reorganizing streams and designs to promote minimalism. This enhances the speed of production.

Another objective during TQM implementation is dependability. This means timely working to ensure that customers get their products within the promised time. Toyota has included a just-in-time production system comprised of multi-skilled employees who work in teams. The kanban control allows the workers to deliver goods and services as promised. Advancing value and effectiveness appears to be the distress for administrators, mechanical specialists, and other Toyota human resources.

During TQM implementation, Toyota responds to the demands by changing its products and the way of doing business. Chary (2009) argues that while implementing TQM, organizations must learn to like change and develop responsive and flexible organizations to deal with the changing business environment.

Within Toyota plants, this incorporates the ability to adopt the manufacturing resources to develop new models. The company is able to attain an elevated degree of suppleness, manufacturing fairly tiny bunches of products devoid of losses in excellence or output.

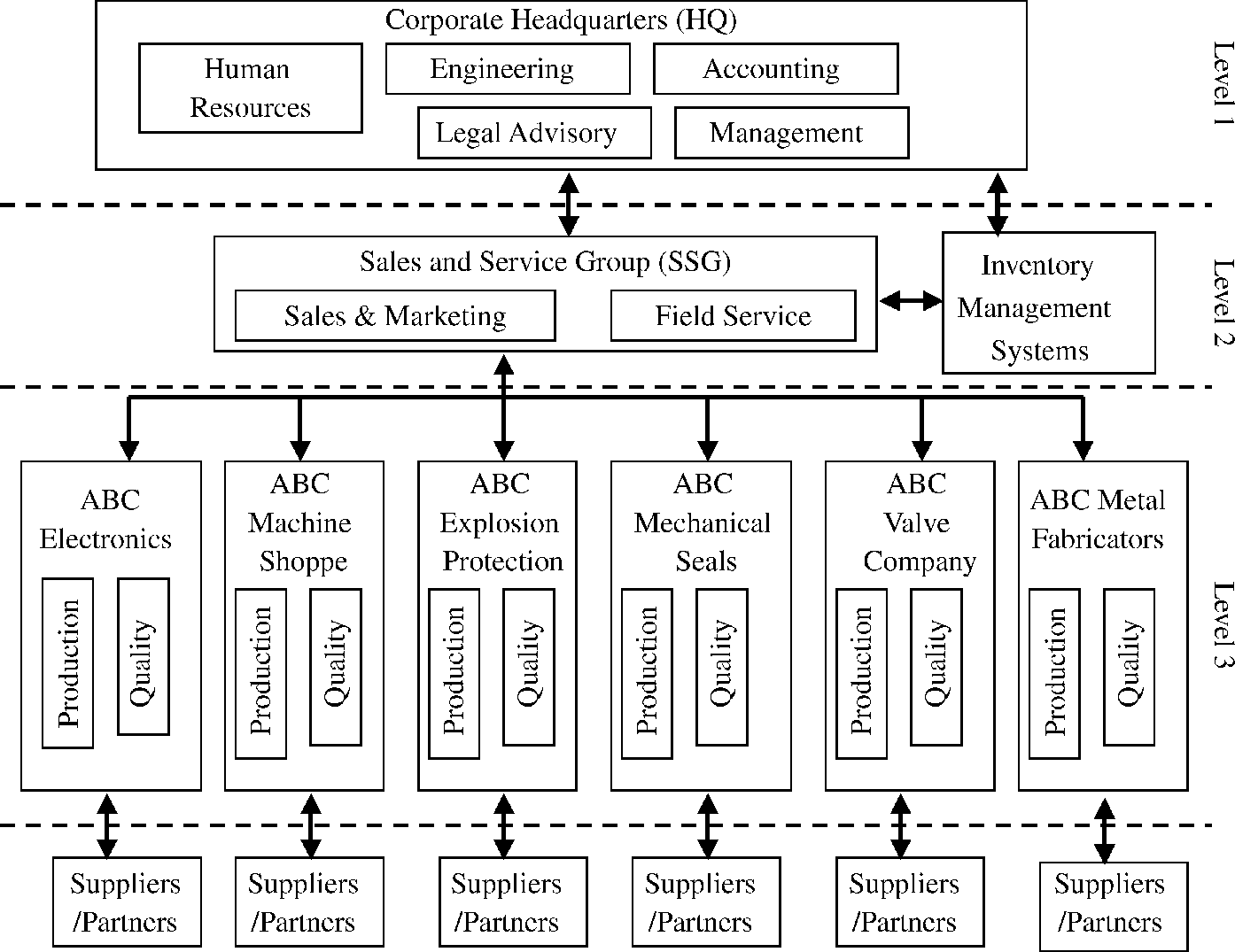

The organizational hierarchy and job descriptions also determine the successful implementation of the TQM. Toyota is amongst the few companies whose organizational structure and task allocation have proved viable in TQM implementation. The company has three levels of management. See the diagram below.

Management hierarchy

Despite the hierarchy and task specification, employees are able to make independent decisions and take corrective measures when necessary to ensure quality during production. Team working is highly encouraged at Toyota Corporation, and this plays a significant role during TQM implementation. All stakeholders are incorporated in quality control initiatives to ensure client demands are satisfied.

However, all employees are required to carry out their assigned tasks, and the management closely supervises the ways of interactions between workers. The management ensures that the manufacturing lines are well-built and all employees are motivated to learn how to improve the production processes.

Toyota is among the few manufacturers in the complete automobile industry that consistently profited during the oil crisis in 1974. The discovery was the unique team working of the Japanese that utilized scientific management rules (Huczynski & Buchanan, 2007).

The joint effort in Japan, usually dubbed Toyotaism, is a kind of job association emphasizing ‘lean-assembly.’ The technique merges just-in-time production, dilemma-answering groups, job equivalence, authoritative foremost-streak administration, and continued procedure perfection.

Just-in-time (JIT) assembly scheme attempts to accomplish all clients’ needs instantly, devoid of misuse but with ideal excellence. JIT appears to be dissimilar from the conventional functional performances in that it emphasizes speedy production and ravage purging that adds to stumpy supply.

Control and planning of many JIT approaches are concerned directly with pull scheduling, leveled scheduling, kanban control, synchronization of flow, and mixed-model scheduling (Slack et al., 2009).

Toyota appears to be amongst the principal participants in changing Japan to a kingpin in car production. Companies, which have adopted the company’s production system, have increased efficiency and productivity. The 2009 industrial survey of manufacturers indicates that many world-class firms have adopted continuous-flow or just-in-time production and many techniques Toyota has been developing many years ago.

In addition, the manufacturing examination of top plant victors illustrates that the mainstream them utilize lean production techniques widely. Thus, team-working TPS assists Toyota Corporation in the implementation of TQM.

Executives and Quality Managers face some challenges while implementing Quality Management Systems in organizations. In fact, with a lack of the implementation resources such as monetary and human resources in any organization, the implementation of TQM cannot be successful. Towards the implementation of programs and projects in organizations, financial and human resources have become the pillar stones.

The approach of TQM impels marketplace competence from all kinds of organizational proceeds to ensure profitability and productivity. To meet the desired results in TQM implementation, an organization ought to consider the availability of human and financial resources that are very important for the provision of an appropriate milieu for accomplishing organizational objectives.

In the case of Toyota, which originated and perfected the philosophy of TQM, the Executives, and Quality Managers met some intertwined problems during TQM implementation. The flaw in the new product development is increasingly becoming complicated for the managers to break and accelerate, thus creating reliability problems. Besides, secretive culture and dysfunctional organizational structure cause barriers in communication between the top management, thus, in turn, augmenting public outrage.

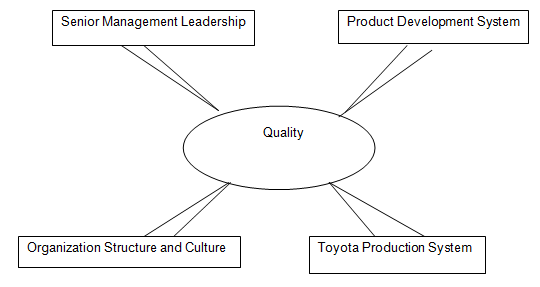

The top executives may fail to provide and scale up adequate training to the suppliers and new workforces. As a result, cracks are created in the rigorous TPS system. In addition, a lack of leadership at the top management might cause challenges in the implementation of TQM. Therefore, in designing the organizational structures and systems that impact quality, the senior executives and managers must be responsible, as elaborated in Figure 2 below.

Total Quality Management is a concept applied in the automobile industry, including the Toyota Corporation. It focuses on continuous improvement across all branches and levels of an organization. Being part of Toyota, the concept defines the way in which the organization can create value for its customers and other stakeholders. Through TQM, Toyota Corporation has been able to create value, which eventually leads to operation efficiencies.

These efficiencies have particularly been achieved by continuous correction of deficiencies identified in the process. A particular interest is the central role that information flow and management have played in enabling TQM initiatives to be implemented, especially through continuous learning and team working culture.

The Toyota way (kaizen), which aims at integrating the workforce suggestions while eliminating overproduction and manufacturing wastes, helps the company to respect all the stakeholders and give clients first priority. The objectives are realized through TPS.

Chary, D. 2009, Production and operations management , Tata McGraw-Hill Education Press, Mumbai.

Huczynski, A. & Buchanan, D. 2007, Organizational behavior; an introductory text, Prentice Hall, New York, NY.

Kanji, G. K. & Asher, M. 1996, 100 methods for total quality management , SAGE Thousands Oak, CA.

Slack, N. et al. 2009, Operations and process management: principles and practice for strategic management, Prentice Hall, New York, NY.

Toyota Motor Corporation 2012, Annual report 2012. Web.

- Google Corporation Investments Evaluation

- How HR Approaches Match Up With the Strategic Initiatives

- Lean Manufacturing: Processes

- Toyota Motor Corporation's Sustainability

- Just-in-Time Techniques, Their Upsides and Downsides

- Barriers and Facilitators of Workplace Learning

- The Science of Behavior in Business

- Standards, models, and quality: Management

- Managerial and Professional Development: Crowe Horwath CPA limited

- Managerial and Professional Development: Deloitte & Touché Company

- Chicago (A-D)

- Chicago (N-B)

IvyPanda. (2019, June 12). Implementation of Total Quality Management (TQM): Toyota Case Study. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/

"Implementation of Total Quality Management (TQM): Toyota Case Study." IvyPanda , 12 June 2019, ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

IvyPanda . (2019) 'Implementation of Total Quality Management (TQM): Toyota Case Study'. 12 June.

IvyPanda . 2019. "Implementation of Total Quality Management (TQM): Toyota Case Study." June 12, 2019. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

1. IvyPanda . "Implementation of Total Quality Management (TQM): Toyota Case Study." June 12, 2019. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

Bibliography

IvyPanda . "Implementation of Total Quality Management (TQM): Toyota Case Study." June 12, 2019. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

- To find inspiration for your paper and overcome writer’s block

- As a source of information (ensure proper referencing)

- As a template for you assignment

IvyPanda uses cookies and similar technologies to enhance your experience, enabling functionalities such as:

- Basic site functions

- Ensuring secure, safe transactions

- Secure account login

- Remembering account, browser, and regional preferences

- Remembering privacy and security settings

- Analyzing site traffic and usage

- Personalized search, content, and recommendations

- Displaying relevant, targeted ads on and off IvyPanda

Please refer to IvyPanda's Cookies Policy and Privacy Policy for detailed information.

Certain technologies we use are essential for critical functions such as security and site integrity, account authentication, security and privacy preferences, internal site usage and maintenance data, and ensuring the site operates correctly for browsing and transactions.

Cookies and similar technologies are used to enhance your experience by:

- Remembering general and regional preferences

- Personalizing content, search, recommendations, and offers

Some functions, such as personalized recommendations, account preferences, or localization, may not work correctly without these technologies. For more details, please refer to IvyPanda's Cookies Policy .

To enable personalized advertising (such as interest-based ads), we may share your data with our marketing and advertising partners using cookies and other technologies. These partners may have their own information collected about you. Turning off the personalized advertising setting won't stop you from seeing IvyPanda ads, but it may make the ads you see less relevant or more repetitive.

Personalized advertising may be considered a "sale" or "sharing" of the information under California and other state privacy laws, and you may have the right to opt out. Turning off personalized advertising allows you to exercise your right to opt out. Learn more in IvyPanda's Cookies Policy and Privacy Policy .

Sign up for the newsletter

Digital editions.

Total quality management: three case studies from around the world

With organisations to run and big orders to fill, it’s easy to see how some ceos inadvertently sacrifice quality for quantity. by integrating a system of total quality management it’s possible to have both.

Top 5 ways to manage the board during turbulent times Top 5 ways to create a family-friendly work culture Top 5 tips for a successful joint venture Top 5 ways managers can support ethnic minority workers Top 5 ways to encourage gender diversity in the workplace Top 5 ways CEOs can create an ethical company culture Top 5 tips for going into business with your spouse Top 5 ways to promote a healthy workforce Top 5 ways to survive a recession Top 5 tips for avoiding the ‘conference vortex’ Top 5 ways to maximise new parents’ work-life balance with technology Top 5 ways to build psychological safety in the workplace Top 5 ways to prepare your workforce for the AI revolution Top 5 ways to tackle innovation stress in the workplace Top 5 tips for recruiting Millennials

There are few boardrooms in the world whose inhabitants don’t salivate at the thought of engaging in a little aggressive expansion. After all, there’s little room in a contemporary, fast-paced business environment for any firm whose leaders don’t subscribe to ambitions of bigger factories, healthier accounts and stronger turnarounds. Yet too often such tales of excess go hand-in-hand with complaints of a severe drop in quality.

Food and entertainment markets are riddled with cautionary tales, but service sectors such as health and education aren’t immune to the disappointing by-products of unsustainable growth either. As always, the first steps in avoiding a catastrophic forsaking of quality begins with good management.

There are plenty of methods and models geared at managing the quality of a particular company’s goods or services. Yet very few of those models take into consideration the widely held belief that any company is only as strong as its weakest link. With that in mind, management consultant William Deming developed an entirely new set of methods with which to address quality.

Deming, whose managerial work revolutionised the titanic Japanese manufacturing industry, perceived quality management to be more of a philosophy than anything else. Top-to-bottom improvement, he reckoned, required uninterrupted participation of all key employees and stakeholders. Thus, the total quality management (TQM) approach was born.

All in Similar to the Six Sigma improvement process, TQM ensures long-term success by enforcing all-encompassing internal guidelines and process standards to reduce errors. By way of serious, in-depth auditing – as well as some well-orchestrated soul-searching – TQM ensures firms meet stakeholder needs and expectations efficiently and effectively, without forsaking ethical values.

By opting to reframe the way employees think about the company’s goals and processes, TQM allows CEOs to make sure certain things are done right from day one. According to Teresa Whitacre, of international consulting firm ASQ , proper quality management also boosts a company’s profitability.

“Total quality management allows the company to look at their management system as a whole entity — not just an output of the quality department,” she says. “Total quality means the organisation looks at all inputs, human resources, engineering, production, service, distribution, sales, finance, all functions, and their impact on the quality of all products or services of the organisation. TQM can improve a company’s processes and bottom line.”

Embracing the entire process sees companies strive to improve in several core areas, including: customer focus, total employee involvement, process-centred thinking, systematic approaches, good communication and leadership and integrated systems. Yet Whitacre is quick to point out that companies stand to gain very little from TQM unless they’re willing to go all-in.

“Companies need to consider the inputs of each department and determine which inputs relate to its governance system. Then, the company needs to look at the same inputs and determine if those inputs are yielding the desired results,” she says. “For example, ISO 9001 requires management reviews occur at least annually. Aside from minimum standard requirements, the company is free to review what they feel is best for them. While implementing TQM, they can add to their management review the most critical metrics for their business, such as customer complaints, returns, cost of products, and more.”

The customer knows best: AtlantiCare TQM isn’t an easy management strategy to introduce into a business; in fact, many attempts tend to fall flat. More often than not, it’s because firms maintain natural barriers to full involvement. Middle managers, for example, tend to complain their authority is being challenged when boots on the ground are encouraged to speak up in the early stages of TQM. Yet in a culture of constant quality enhancement, the views of any given workforce are invaluable.

AtlantiCare in numbers

5,000 Employees

$280m Profits before quality improvement strategy was implemented

$650m Profits after quality improvement strategy

One firm that’s proven the merit of TQM is New Jersey-based healthcare provider AtlantiCare . Managing 5,000 employees at 25 locations, AtlantiCare is a serious business that’s boasted a respectable turnaround for nearly two decades. Yet in order to increase that margin further still, managers wanted to implement improvements across the board. Because patient satisfaction is the single-most important aspect of the healthcare industry, engaging in a renewed campaign of TQM proved a natural fit. The firm chose to adopt a ‘plan-do-check-act’ cycle, revealing gaps in staff communication – which subsequently meant longer patient waiting times and more complaints. To tackle this, managers explored a sideways method of internal communications. Instead of information trickling down from top-to-bottom, all of the company’s employees were given freedom to provide vital feedback at each and every level.

AtlantiCare decided to ensure all new employees understood this quality culture from the onset. At orientation, staff now receive a crash course in the company’s performance excellence framework – a management system that organises the firm’s processes into five key areas: quality, customer service, people and workplace, growth and financial performance. As employees rise through the ranks, this emphasis on improvement follows, so managers can operate within the company’s tight-loose-tight process management style.

After creating benchmark goals for employees to achieve at all levels – including better engagement at the point of delivery, increasing clinical communication and identifying and prioritising service opportunities – AtlantiCare was able to thrive. The number of repeat customers at the firm tripled, and its market share hit a six-year high. Profits unsurprisingly followed. The firm’s revenues shot up from $280m to $650m after implementing the quality improvement strategies, and the number of patients being serviced dwarfed state numbers.

Hitting the right notes: Santa Cruz Guitar Co For companies further removed from the long-term satisfaction of customers, it’s easier to let quality control slide. Yet there are plenty of ways in which growing manufacturers can pursue both quality and sales volumes simultaneously. Artisan instrument makers the Santa Cruz Guitar Co (SCGC) prove a salient example. Although the California-based company is still a small-scale manufacturing operation, SCGC has grown in recent years from a basement operation to a serious business.

SCGC in numbers

14 Craftsmen employed by SCGC

800 Custom guitars produced each year

Owner Dan Roberts now employs 14 expert craftsmen, who create over 800 custom guitars each year. In order to ensure the continued quality of his instruments, Roberts has created an environment that improves with each sale. To keep things efficient (as TQM must), the shop floor is divided into six workstations in which guitars are partially assembled and then moved to the next station. Each bench is manned by a senior craftsman, and no guitar leaves that builder’s station until he is 100 percent happy with its quality. This product quality is akin to a traditional assembly line; however, unlike a traditional, top-to-bottom factory, Roberts is intimately involved in all phases of instrument construction.

Utilising this doting method of quality management, it’s difficult to see how customers wouldn’t be satisfied with the artists’ work. Yet even if there were issues, Roberts and other senior management also spend much of their days personally answering web queries about the instruments. According to the managers, customers tend to be pleasantly surprised to find the company’s senior leaders are the ones answering their technical questions and concerns. While Roberts has no intentions of taking his manufacturing company to industrial heights, the quality of his instruments and high levels of customer satisfaction speak for themselves; the company currently boasts one lengthy backlog of orders.

A quality education: Ramaiah Institute of Management Studies Although it may appear easier to find success with TQM at a boutique-sized endeavour, the philosophy’s principles hold true in virtually every sector. Educational institutions, for example, have utilised quality management in much the same way – albeit to tackle decidedly different problems.

The global financial crisis hit higher education harder than many might have expected, and nowhere have the odds stacked higher than in India. The nation plays home to one of the world’s fastest-growing markets for business education. Yet over recent years, the relevance of business education in India has come into question. A report by one recruiter recently asserted just one in four Indian MBAs were adequately prepared for the business world.

RIMS in numbers

9% Increase in test scores post total quality management strategy

22% Increase in number of recruiters hiring from the school

20,000 Increase in the salary offered to graduates

50,000 Rise in placement revenue

At the Ramaiah Institute of Management Studies (RIMS) in Bangalore, recruiters and accreditation bodies specifically called into question the quality of students’ educations. Although the relatively small school has always struggled to compete with India’s renowned Xavier Labour Research Institute, the faculty finally began to notice clear hindrances in the success of graduates. The RIMS board decided it was time for a serious reassessment of quality management.

The school nominated Chief Academic Advisor Dr Krishnamurthy to head a volunteer team that would audit, analyse and implement process changes that would improve quality throughout (all in a particularly academic fashion). The team was tasked with looking at three key dimensions: assurance of learning, research and productivity, and quality of placements. Each member underwent extensive training to learn about action plans, quality auditing skills and continuous improvement tools – such as the ‘plan-do-study-act’ cycle.

Once faculty members were trained, the team’s first task was to identify the school’s key stakeholders, processes and their importance at the institute. Unsurprisingly, the most vital processes were identified as student intake, research, knowledge dissemination, outcomes evaluation and recruiter acceptance. From there, Krishnamurthy’s team used a fishbone diagram to help identify potential root causes of the issues plaguing these vital processes. To illustrate just how bad things were at the school, the team selected control groups and administered domain-based knowledge tests.

The deficits were disappointing. A RIMS students’ knowledge base was rated at just 36 percent, while students at Harvard rated 95 percent. Likewise, students’ critical thinking abilities rated nine percent, versus 93 percent at MIT. Worse yet, the mean salaries of graduating students averaged $36,000, versus $150,000 for students from Kellogg. Krishnamurthy’s team had their work cut out.

To tackle these issues, Krishnamurthy created an employability team, developed strategic architecture and designed pilot studies to improve the school’s curriculum and make it more competitive. In order to do so, he needed absolutely every employee and student on board – and there was some resistance at the onset. Yet the educator asserted it didn’t actually take long to convince the school’s stakeholders the changes were extremely beneficial.

“Once students started seeing the results, buy-in became complete and unconditional,” he says. Acceptance was also achieved by maintaining clearer levels of communication with stakeholders. The school actually started to provide shareholders with detailed plans and projections. Then, it proceeded with a variety of new methods, such as incorporating case studies into the curriculum, which increased general test scores by almost 10 percent. Administrators also introduced a mandate saying students must be certified in English by the British Council – increasing scores from 42 percent to 51 percent.

By improving those test scores, the perceived quality of RIMS skyrocketed. The number of top 100 businesses recruiting from the school shot up by 22 percent, while the average salary offers graduates were receiving increased by $20,000. Placement revenue rose by an impressive $50,000, and RIMS has since skyrocketed up domestic and international education tables.

No matter the business, total quality management can and will work. Yet this philosophical take on quality control will only impact firms that are in it for the long haul. Every employee must be in tune with the company’s ideologies and desires to improve, and customer satisfaction must reign supreme.

Contributors

- Industry Outlook

Total Quality Management (TQM) Implementation in Modern Businesses

In today’s competitive business environment, ensuring peak level of quality management is not just a goal; but its necessity to remain competitive and in a market leading position. Companies across the globe are striving hard to adopt methods that ensure efficiency, operational excellence and customer satisfaction.

Total quality management (TQM ) has revolutionized the industry by embedding quality into every step of the production process and employees in the organization. . According to the latest research by the Harvard Business Review the organizations successfully implementing TQM have observed a staggering 40% growth in productivity and a 25% reduction in the cost within the initial years.

This blog article aims to explore the Implementation of Total Quality management a cross different industries.

Overview of Total Quality Management (TQM)

Before delving into the importance of Total quality management and its impact on sustainable business success, let’s dive into the overview of this comprehensive management system.

Total quality management (TQM) is a systematic approach designed to improve the overall performance of an organization at every stage of production and delivery goods and services to end users or customers.

The core principles of TQM include placing the customer at the center of everything the organization does, continuous improvement plans, effective communication, decision-making approach to rectify problems and customer centered strategies. The quality pioneers who set total quality management examples in the early 20th century include W. Edwards Deming, Joseph Juran, and Kaoru Ishikawa.

These leading thinkers of the time initially adopted TQM principles and sparked a revolution, establishing cornerstones of modern business practices and management thinking.

TQM is adaptable and flexible,evolving with technological advancement and shifting market dynamics with each passing day to the organizations that use TQM methodology as a guiding framework for their operations.

TQM Practices in Toyota

Toyota, one of the early adopters, sets a benchmark in the implementation of Total Quality Management (TQM), with a commitment to excellence that permeates from the higher management to everyone in the organization. . The main strategies, such as multi-skilled and self motivated employees, staff empowerment, standardization and active involvement, have brought tremendous improvements in customer satisfaction, brand recognition and increased popularity and sales for Toyota. . These strategies have aided the Toyota Management System in reducing cost, eliminating bottlenecks , and maximizing production efficiency.

A key aspect of Toyota’s TQM is the Just-in-Time system adopted from Henry Ford’s production model. This system reduces the requirement of work in process inventory by focusing on a multi-skilled force and streamlining production.

Improved quality checks at the right point in the process, mistake-proofing procedures and decentralized decision-making process ensure continuous improvement and high-quality products, helping Toyota emerge as a leader in quality management.

Key Elements of TQM Implementation

Leadership and management commitment:.

Leadership plays a crucial role in fostering a quality culture. Supervisors must maintain a healthy environment of commitment and provide the resources required to achieve clear goals for quality improvement.

Employee Involvement:

Various successfu l Total Quality Management examples confirm t hat employee engagement is essential for TQM implementation. Employee involvement in decision-making and problem-solving processes fosters an ownership approach, leading towards improvement and innovation.

Customer Focus:

Customers are the lifeblood of any business and the reason a company exists. Similarly, the triumphant journey of TQM’s success revolves around prioritizing customers. Continuously gathering customer feedback and analyzing their requirements helps exceed expectations.

TQM Practices Across Industries

Manufacturing sector:.

The manufacturing industry has long embraced TQM strategies. Lean manufacturing stands out as a leading example, focusing on waste reduction and process optimization. Companies Like Motorola and General Electric have embarked on successful journeys due to quality improvement programs guided by TQM .

Service Industry:

In this sector, TQM emphasizes customer service excellence and process efficacy. Hospitality giants like Ritz-Carlton employ TQM strategies to enhance guest experiences and streamline workflow. Continuous training and feedback from customers leading to training and improvement actions are crucial for improving service standards.

Healthcare Industry:

TQM in healthcare improves patient care, reduces errors and improves safety measures. Healthcare providers ensure quality control measures and engage in continuous staff training. Mayo clinic and cleveland clinic are one of the finest examples where TQM is making wonders for better patient outcomes and operational efficiency.

Benefits of TQM Implementation

Improved quality:.

Correct TQM implementation guarantees superior quality products and services like error correction and defect rectification. The outcome results in increased positive customer feedback and trust in the brand.

Enhanced Customer Satisfaction:

By prioritizing a customer’s needs and addressing their expectations, TQM fosters stronger relationships with customers and promotes loyalty. Satisfied customers are more likely to return for repeat purchase and recommend business to others.

Operational Efficiency:

TQM assures that by maintaining operational efficiency, the processes are streamlined, waste is reduced and resources are utilized at the most efficient level. This leads to cost saving and upsurges in profit margin.

Challenges in TQM Implementation

Resource allocation:.

Recent research by the Institute of Quality Assurance reveals that financial resources are a significant hurdle for 45% of companies in TQM implementation. Numerous total quality management case studies expose the fact that facilitating adequate financial and human resources can be challenging for some organizations.

Change Management:

Adopting TQM involves significant changes in organizational culture and practices. These adaptations can be difficult for employees and management to integrate. Resistance to change by the staff and management can hinder the implementation of total quality management.

Sustaining Momentum:

It’s not only about implementing TQM but also about maintaining the initiatives over a longer period of time. This requires continuous focus from management on customer centricity, employee training and standard quality procedures which are regularly updated.Sustaining momentum requires continuous efforts and regular reviews. Organizations must adapt new strategies to continue the improvement process and avoid stagnation.

Strategies for Successful TQM Implementation

Training and development:, one of the most important processes that assures successful tqm implementation is consistency in training and development programs for the workforce. the training related to implementation of total quality management aids employees in understanding principle and process, leading to better adaptability., clear communication:.

Organizational goals must be crystal clear and this can only be possible by establishing clear communication channels. Management must ensure that everyone in the team is on the same page.Transparency and frequent updates promotes chances of focus and motivation among the team.

Continuous Improvement:

Continuous improvement is only possible by cultivating a culture of regular performance updates and feedback. These responses help in identifying the loopholes and sustain the quality initiatives taken by the organization.

Key Takeaways

In a nutshell, TQM holds immense significance for modern business aiming to achieve operational excellence and long-term success. The practices adopted in TQM’s implementation have demonstrated effectiveness across various industries.

With ongoing technological advancement, TQM will persistently adapt to market dynamics, offering fresh avenues for innovation in business ventures.

Adopting TQM is essential for attaining business excellence, as it empowers organizations to generate value for clients and stakeholders, assuring success in the competitive market place.

Latest Article & Content

- Plant Inspections and lubrication schedule

- Breakdown maintenance

- Cost reduction programs

- Improving Oee in Business Operations

- Toll Production and Production Outsourcing

- Country and Work Culture in South east Asia

- Discounted Payback period

- Payback Period

- How to Do Root Cause Analysis in 6 Steps?

- Takt Time: What Is It And How To Measure It?

- Gross Profit vs. Operating Income: 3 Reasons to Measure Both

- Eliminating and Reduction of The 7 Wastes of Lean Production

- Little’s Law: The Road To Stable And Predictable Systems

- The Benefits Of Root Cause Analysis In Continuous Improvement

- Definition Of Value In Lean Manufacturing

- Lean Methods To Improve Material Flow

- Understanding Cost Per Unit: A Comprehensive Guide

- Reduce Inventory Costs: Effective Strategies for Inventory Management

Subscribe to our Newsletter

leanmanufacture.net is a web resource and blog style website where you can find out more about lean manufacturing, operations management and business strategy from concepts and theory to real life applications which will help you achieve your operations goals and objectives.

You may be interested in

- W. Edwards Deming’s 14 points on Quality applied in today’s business world

- Create winning teams: How to make training staff more effective

- Strengthening the core: Nurturing the Core Business of Your Company

- Why working capital is important? what you should know

- Privacy Policy

- Terms & Condition

IMAGES

VIDEO

COMMENTS

Coca-Cola also uses Total Quality Management (TQM), which involves the management of quality at every level of the organisation, including; suppliers, production, customers etc. This allows Coca-cola to retain/regain competitiveness to achieve increased customer satisfaction.

Looking for a total quality management case study on Toyota? 🔥 Read our research report to learn about ️ the implementation of TQM, ️ how Toyota manages quality in all organization management system, and more!

Total quality management: three case studies from around the world – European CEO. With organisations to run and big orders to fill, it’s easy to see how some CEOs inadvertently sacrifice quality for quantity. By integrating a system of total quality management it’s possible to have both.

Abstract. For many years, the Toyota Motor Company was widely considered to be a leader in quality management. Based partly on this reputation and the perceived quality of its products, the...

Total quality management (TQM) is a systematic approach designed to improve the overall performance of an organization at every stage of production and delivery goods and services to end users or customers.

Total Quality Management (TQM) Benefit: Methodology Creates an Adaptive Organization. ASQ has collected a series of total quality management case studies to illustrate the impact a TQM system can have on your organization.

An analysis of three applications of Total Quality Management (TQM) in the government sector demonstrates the importance of leadership and a unified organizational vision.

Total Quality Management: Key Concepts and Case Studies provides the full range of management principles and practices that govern the quality function. The book covers the fundamentals and...

Total Quality Management: Key Concepts and Case Studies provides the full range of management principles and practices that govern the quality function. The book covers...

'TQM: Text with Cases' is clearly written in a logical manner and points are supported by real life case studies. Professor Oakland demonstrates how a Total Quality Management strategy...